Aasta Hansteen offshore field (previously Luva) is located in 1,300m of water in the Norwegian Sea, approximately 300km from the Nordland County offshore Norway. It represents the deepest ever subsea development in the Norwegian Continental Shelf.

Aasta Hansteen project is jointly owned by Equinor (formerly Statoil Petroleum, 51%), Wintershall (24%), OMV (15%) and ConocoPhillips Skandinavia (10%). Equinor, which holds the majority share, is the project operator.

Equinor submitted the plan for development and operation of the Aasta Hansteen field to the Ministry of Petroleum and Energy (MPE) in December 2012 and the same was accepted in 2013. The MPE’s Norwegian Petroleum Directorate (NPD) granted the development and production exemption for the development of Snefrid Nord gas field in October 2017.

The NPD approved the start of gas production from the Aasta Hansteen facility in August 2018. The estimated investment in the Aasta Hansteen development is Nkr37.5bn ($4.6bn).

Aasta Hansteen comprises the joint development of the Luva, Haklang, Snefrid South and Snefrid North fields. First production from the field was achieved in December 2018.

Aasta Hansteen offshore field discovery and reserves

Aasta Hansteen offshore gas field was discovered by BP with the drilling of the 6707/10-1 well in April 1997. The field reservoir is located at a depth of 3,000m in Cretaceous sandstone in the Nise formation.

Equinor acquired the field in 2006 and drilled an appraisal well (6706/12-1) using Transocean Leader drilling rig in 2008.

The total recoverable gas reserves of the project are estimated to be 55.6 billion standard cubic meters (Sm³).

Aasta Hansteen offshore field development details

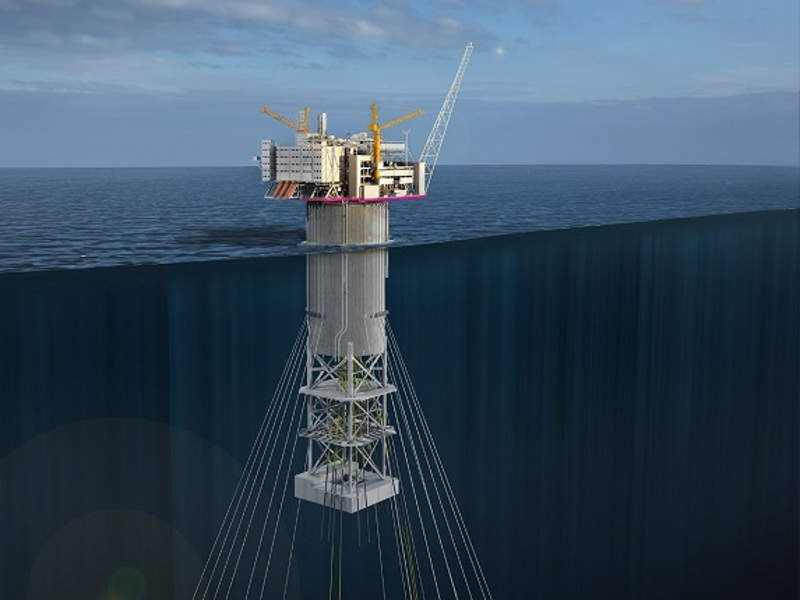

Aasta Hansteen offshore field is developed by a single point anchor reservoir (SPAR) floating production storage and offloading facility (FPSO) along with two subsea templates. Pipelines and steel catenary risers connect the subsea-templates to the SPAR platform.

A total of seven production wells have been drilled at the field to recover the gas using natural aquifer drive and pressure depletion.

The produced gas is transported by the 480km-long Polarled pipeline to the Nyhamna gas substation located at Møre og Romsdal county in the western part of Norway, for further export to Europe.

The Polarled pipeline is operated by Gassco and is also connected to different fields located in the Norwegian Sea.

Aasta Hansteen SPAR FPSO details

The 339m-tall Aasta Hansteen SPAR FPSO weighs 70,000t and is installed in 1,300m of water. It consists of a vertical column moored to the seabed, an integrated deck, and a lower substructure or hull. It is the biggest SPAR platform in the world and the first in the Norwegian Continental Shelf.

The integrated deck of the FPSO features topsides measuring 100mx50mx56m and weighing 24,000t. The topsides have the capacity to produce 23 million cubic metres of oil and gas a day.

The substructure or hull of the SPAR is a cylindrical semi-submerged production platform with a length and diameter of 200m and 50m respectively. The height and weight of the hull are 195m and 46,000t respectively, while the storage capacity is 160,000 barrels of condensate.

Contractors involved

Equinor awarded the $1.1bn engineering, procurement, installation, and commissioning contract for the topside and hull/substructure of the SPAR FPSO in January 2013 to Hyundai Heavy Industries (HHI).

HHI subcontracted Boskalis for the transportation of SPAR’s hull and topside from its shipyard in South Korea to the field. The transportation was completed by Dockwise, a wholly-owned subsidiary of Boskalis.The contract to supply LM6000 advanced aero-derivative gas turbine technology for the gas field was awarded to GE in May 2013.

HHI also subcontracted Lankhorst Ropes for providing deepwater mooring ropes for the SPAR installation in 2014.

Equinor awarded the marine and subsea contract worth $0.2bn to Subsea 7 in 2013, while Aker Solutions and Technip were awarded a front-end engineering and design (FEED) contract for the SPAR platform in March 2012.

PG Flow Solutions provided hypochlorite pump skid, as well as large chemical injection module and sump pump packages for the project.

The FEED study for the topsides of SPAR was completed by McDermott in 2018.

Kværner was involved in the mechanical work related to the installation of the hull of the SPAR. The work included welding of hull and tire connection and installation of pumps and fittings for riser pipes and connection of systems.

ABB provided telecommunication systems, while IKN Ocean Design provided flow-line concept engineering services for the project in 2012.