Global pressure on the use of traditional fossil fuels and the emission of greenhouse gases such as CO2 is enormous. However, not only CO2 and greenhouse gases cause negative emissions. Nitrogen oxides (NOx) emissions from power plants have emerged as a significant environmental concern due to their detrimental effects on human health and the ecosystem. This abstract summarizes the imperative need for reducing NOx emissions from open cycle gas turbine (OCGT) plants globally.

Governments worldwide have implemented stringent emission standards to mitigate NOx pollution. These regulations compel power plants to adopt technologies such as Selective Catalytic Reduction (SCR) and Low-NOx burners to reduce NOx emissions to permissible levels. Increased concern about public health, environmental impact, air quality standards and more international standards on emissions drive countries to implement stricter NOx emission regulations on the short term. Also, the move from natural gas towards hydrogen as fuel will drive the needs to reduce NOx emissions further.

The implementation of Selective Catalytic Reduction (SCR) systems in gas turbine plants is essential for mitigating nitrogen oxides (NOx) emissions, a major contributor to air pollution and environmental degradation. Gas turbine plants, while efficient in power generation, often produce significant amounts of NOx due to high combustion temperatures. The trend toward hydrogen as fuel will trigger further concern on NOx emission and with current natural gas plant being made read for hydrogen, also these plants need to be ready to reduce NOx in a future hydrogen scenario. SCR systems facilitate the conversion of harmful NOx into harmless nitrogen and water vapor through chemical reactions with ammonia over a catalyst surface. This process enables gas turbine plants to meet stringent emission regulations while maintaining operational efficiency. The necessity for SCR systems underscores the imperative of sustainable energy practices and environmental stewardship in the operation of gas turbine plants, contributing to cleaner air and healthier ecosystems.

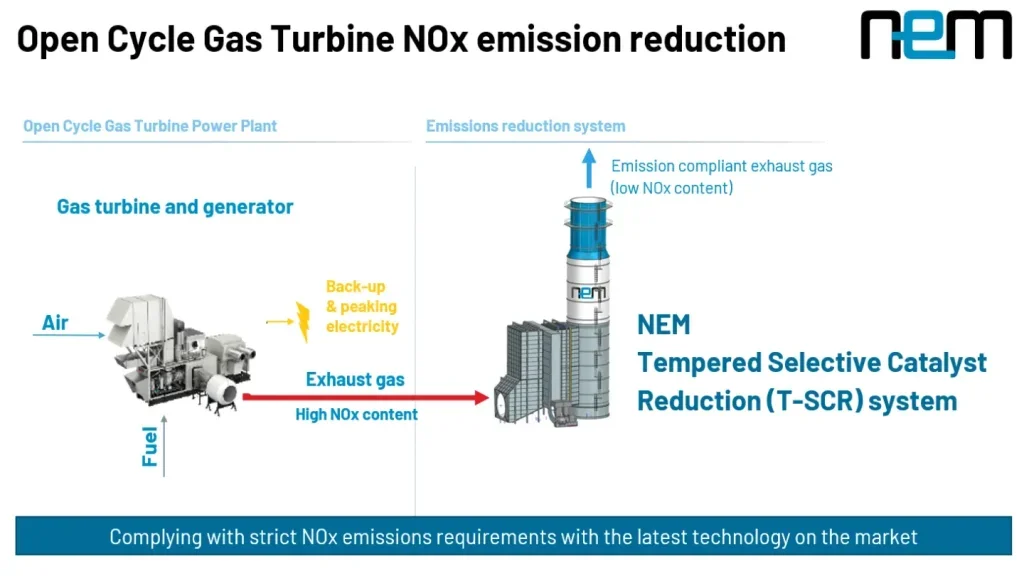

Many open cycle gas turbines today utilize hot catalyst in a Selective Catalytic Reduction (SCR) system which offers certain advantages in reducing nitrogen oxides (NOx) emissions in a temperature range between 300°C to 500°C. However, going to higher temperatures the hot SCR catalyst comes with various drawbacks as, for instance, the need for high volumes of catalyst materials, leading to high operating costs. Typically, smaller gas turbines, up to 30-40 MW output, have low exhaust gas temperature, while medium size and larger turbines go up to very high exhaust gas temperatures, higher than 600 degrees Celsius. With predicted lower operating hours for new gas turbine plants, often units are being installed in Open Cycle, also the larger ones, since these are planned to run only for peaking or intermediate power needs. These higher temperature gas turbines need to reduce NOx emissions using other technology than the typical hot SCR systems.

NEM Energy has developed a solution for NOx reduction in Open Cycle Gas Turbine plants using tempered air in an SCR system. Utilizing tempered air in Selective Catalytic Reduction (SCR) systems offers distinct advantages over employing a hot catalyst. By mixing the flue gas with the incoming air to a moderate temperature before it enters the catalyst chamber, tempered air SCR systems (T-SCR) achieve effective NOx reduction while mitigating some of the drawbacks associated with high-temperature operation. Compared to hot catalysts, tempered air SCR systems offer enhanced control over reaction kinetics, reducing the risk of thermal stress-induced catalyst degradation and minimizing energy consumption. By saving on the operational expenses, the T-SCR system offers the lowest total cost of ownership. The use of tempered air facilitates more efficient NOx reduction while maintaining operational flexibility and safety, making it a preferred option for achieving emission reduction targets in OCGTs.