The passion we share to achieve a net zero future is heavily reliant upon renewable energy sources. With hydropower representing the largest source of renewable energy, and the requirement to increase hydro output by 3% annually to achieve this goal according to the IEA, it is critical to not only maintain but also increase hydro generation levels. However, over the past five years, less than half of the required increase in output has been achieved.

The average age of hydro generators in established markets such as North America and Europe exceeds 40 years old which is of serviceable age, presenting a significant risk to the installed base of hydro generation. In addition, the opportunity to build new hydro facilities in these regions is limited by suitable locations that haven’t already been utilised, and the investment required to build them which is made challenging by legislation and the economic pressures.

So, it is difficult to build new hydro infrastructure in North America and Europe, and the existing fleet requires refurbishment and modernisation, yet there is a desire to increase the amount of energy being generated by hydro. While the expectation in the industry is for high-quality formed windings that last for decades. Therefore, a solution is favourable that provides a high-quality and reliable refurbishment, while an opportunity is present to utilize the existing assets to increase the output of these assets.

Preformed Windings has identified this challenge and opportunity in the market, and due to its independent status as purely a product manufacturer is well-positioned to collaborate with the industry to carry out research and development related specifically to high-voltage windings. This R&D made up of over 25,000 hours over the past three years, and in collaboration with leading OEMs and insulation manufacturers has resulted in significant steps forward in winding technology.

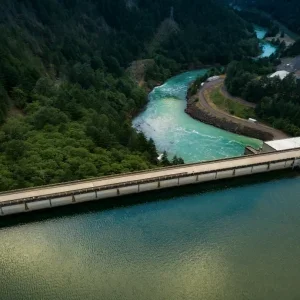

The hydro industry is already benefiting from this. For example, Project Holter, which was voted a finalist at the prestigious AEMT awards, resulted in a modernization program at the Holter dam in Montana, US, which upgraded the output of its six generators by 42%, resulting in enough renewable energy to power 16,500 additional homes and businesses in the surrounding area. This example, involving a redesign of the turbines and generator core, highlights the opportunity across the industry, and when compared to developing new hydro facilities this approach is also exceptionally cost-effective.

James Stevens MBA, BEng (Hons), Global Sales and Marketing Director of Preformed Windings says: “We are dedicated to a sustainable future and excited to collaborate with leading organizations and end-users in the industry to answer a specific and solvable problem; how do we modernize this ageing fleet and capitalize on the huge untapped potential of additional hydropower generation from existing assets using a circular economy approach.”

Output gains

Due to the age of much of the installed base, there are often significant output gains achievable without major redesign activities beyond the windings. For example, the principle of increasing the output of generators centres around increased output and improved efficiency. Both of these can be achieved by utilizing the available slot space in the core of the generator more effectively, capitalizing on advancements in insulation technology and cutting-edge manufacturing techniques to increase the number of turns and or cross-sectional area of the copper. While optimising the design of the coil geometry and achieving exceptionally tight tolerance can offer benefits such as reduced mean-turn-length of the coils and uniform windings. When coupled with coil specifications that offer previously unheard-of levels of Tan Delta and Partial discharge levels, the result is a refurbishment of the generator designed to last and with increased performance.

GE Renewables says: “We enjoy collaborative and cutting-edge research and development with Preformed Windings, which positions both organisations as thought leaders in the hydro industry. Their products offer significant benefits such as very low partial discharge and a long service life”

While Sidewinders LLC says: “Preformed Windings supplies exceptionally high-quality HV diamond coils for hydrogenerators, along with 24/7 technical support. Preformed Windings’ engineers listen to each client’s needs and study the specific requirements of each project to provide precisely tailored solutions. Preformed Windings uses their position as trusted thought leaders in the industry to not simply manufacture replacement coils, but to substantially improve coil designs”

While huge opportunities for the development of the existing hydro installed base, and many other industries such as Nuclear power generation have been identified, Preformed Windings said it is dedicated to continuing investment in thought leadership. In 2023 approximately £2.5 million is being invested by the company to develop quality-led manufacturing processes and carry out R&D while increasing the capacity of our manufacturing facility to satisfy the global demand for high-quality windings.

This article first appeared in International Water Power magazine.