After decades of production in the USA, an uprated facility in France is now producing TRIGA uranium zirconium hydride fuel for use in both research reactors and a new generation of smaller SMRs

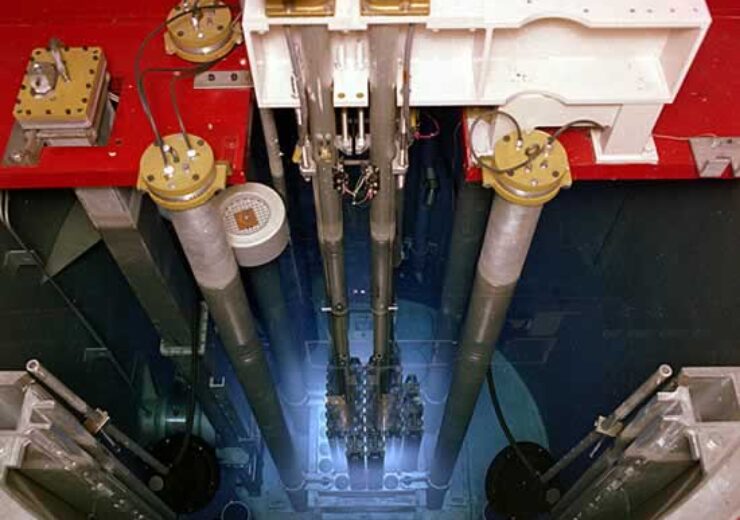

Nuclear reactor core of a Triga research reactor. (Credit: Tungsten/Wikimedia Commons)

TRIGA – Training, Research, Isotopes, General Atomics – is a nuclear reactor model designed by General Atomics and used for research and training activities by scientific institutions and universities. There are currently 36 TRIGA reactors in operation around the world. The TRIGA reactor uses unique low-enriched, long-lifetime uranium zirconium hydride (UZrH) fuel which has the desirable characteristics of a large negative fuel temperature coefficient. This means that as the temperature rises, reactivity rapidly decreases and while the reactor can be briefly pulsed to very high energy outputs (up to 22 GW reported) it is a very safe design. The fuel is the fundamental feature of the TRIGA family of reactors and accounts for its widely recognised safety, rugged, dependable performance, economy of operation, and its acceptance worldwide.

Along with ongoing research programmes, reactor designers have been inspired by the TRIGA fuel design and technology and are currently exploring applications for smaller reactors. Among those designs is the US Department of Energy’s MARVEL microreactor project. The MARVEL microreactor is a sodium-potassium-cooled microreactor that will generate 100 kW of power. MARVEL fuel uses the same UZrH bars as TRIGA fuel and it leverages existing manufacturing capabilities too. It also benefits from the same safety advantages and robust regulatory processes. The US DOE recently agreed to purchase 668 new fuel elements over the next nine years, for INL’s new MARVEL microreactor project.

Moving TRIGA fuel production

From 1958 to 1995 all TRIGA fuel was fabricated at the General Atomics campus in San Diego to support the US research reactor programmes designed to develop highly-trained scientists to support the future nuclear workforce. Due to reduced fuel demand and increasing licensing requirements, General Atomics was interested in relocating its fuel fabrication facility while maintaining the fuel supply for these research reactors.

Meanwhile, the US Department of Energy (DOE) was financing a programme to convert TRIGA reactors still running on higher enriched uranium (HEU) fuel to lower enriched uranium (LEU) fuel. This DOE programme was securing business for the future, further driving General Atomics desire to find a partner that could manufacture TRIGA fuel among other fuel manufacturing activities and to make it more cost-effective.

At the same time, Framatome’s CERCA fuel entity and manufacturing facility located in Romans, France, was exploring new business opportunities to build on its expertise and manufacturing backlog. As a manufacturer of metallic fuels for research reactors, CERCA was selected as the preferred partner for General Atomics. Framatome and General Atomics created the TRIGA International SAS joint venture in 1995 to market TRIGA fuel elements manufactured by CERCA.

Today, Framatome CERCA is the only supplier of uranium-zirconium hydride (UZrH) fuel for use in TRIGA-type research reactors.

In 2018, a refurbishment project was initiated to address the fuel needs of the US TRIGA reactors and to bring the facility up to modern state-of-the-art safety standards. The project was made possible with funding from the US DOE and capital from TRIGA International. The DOE was a catalyst in providing nearly $16m in support of the facility upgrades also funded by Framatome. The National Nuclear Security Administration provided $5m in initial funding to perform feasibility studies and assist with the design, installation and removal of equipment while the Office of Nuclear Energy provided more than $10m to complete the work to get the production line up and running. Renovations were completed in early 2021.

To produce TRIGA fuel elements, the UZrH alloy is created by melting uranium and zirconium in a graphite mould to obtain UZr bars with a required chemical composition. A surface treatment and hydriding process is then performed to obtain the final UZrH bars. Three of these UZrH bars are assembled using a stainless steel cladding tube and end caps for the final fuel element. The main difference between TRIGA fuel and MARVEL fuel is the number of bars in one fuel element. The MARVEL fuel design requires five fuel bars whereas TRIGA fuel uses three. During the production process inspections are performed at several stages to ensure the integrity of the chemistry and the accuracy of the dimensions. Once confirmed, a final leak test is performed on the finished product prior to distribution.

Uprating production and ensuring quality

Since 2018, a dedicated project team led the work to accommodate new equipment for the upstream and downstream processes at the site. With the latest technologies and advanced functionality, the upgrades included a lathe, grinding machine, cladding units, welding equipment, controls, and melting and hydriding furnaces.

The new equipment is fitted with modern instrumentation and controls for better quality control of the products, better yields in the manufacturing process, and reliable equipment for improved productivity.

In addition, many specialised fields of industry such as metallurgy, chemistry, machining, and welding, can be found within the TRIGA production facility.

Upgrades to the sole source of TRIGA fuel strengthened safety measures and ensured the supply of TRIGA fuel to meet customers’ long-term demands. It means the fuel is also available for advancements in fuel designs for small modular reactors and potential advanced reactor opportunities.

With the necessary approvals from the French Nuclear Authority (ASN), TRIGA International resumed manufacturing operations of enriched zirconium-uranium ingots as scheduled.

Rigorous quality assurance and quality control procedures ensure that the TRIGA fuel meets US standards and qualification requirements, such as the ASME Nuclear Quality Assurance (NAQ-1) certification programme.

Currently, there are 36 operational TRIGA reactors supporting research programmes in the US and around the world. These reactors provide access to nuclear technology and educational and experiential training for the next generation of scientists and engineers operating in the field of nuclear energy. These reactors are critical in gaining and maintaining the specialised competencies of the industry’s personnel now and into the future.

With the advancements being made in the nuclear industry, TRIGA nuclear fuel supports these reactors in their continued operations and in the development of the next generation of the vital clean energy workforce.

This article first appeared in Nuclear Engineering International magazine.