VibrosystM explains how premature ageing of a hydro generator can be detected from the outset

Problems and anomalies with new or refurbished machines often develop unsuspectingly within the first years of operation while still under warranty. By detecting such phenomena at commissioning and throughout the warranty, it is possible to trend their evolution, initiate discussion with the manufacturer, and take immediate corrective actions to ensure long term performance and reliability.

A good case study to illustrate this is the RH Saunders dam on the St Lawrence River in Canada. Shortly after commissioning in 1995, a series of test measurements were performed on a new hydrogenerator using the ZOOM system from vibrosystm.

The tests were to verify the integrity of the new machine’s tolerances and dynamic behaviour and use these as a baseline for future reference.

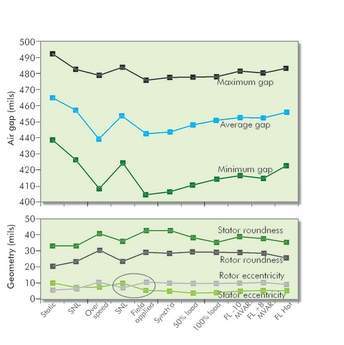

At commissioning the unit maintained good mechanical stability in all operating conditions. Static measurements matched the recommended erection tolerances but the rotor concentricity at full load slightly exceeded erection tolerances. This caused a slight magnetic shift which was also revealed by the vibration data at the generator guide bearing.

As second series of test measurements taken two years later pointed to:

• A significant deterioration of the stator roundness.

• A slight increase in the rotor roundness.

• Improvements in both rotor and stator concentricities.

• A high shaft vibration at the generator guide bearing.

The stator tendency to adopt an oval shape was considered to be abnormal for a two-year unit and was most likely to be a design or assembly problem with the radial key system. It was recommended, while still under warranty, that discussions were initiated with the generator manufacturer to study the problem.

It was also found that several stator hold-down bolts and upper stator brackets had lost radial clearance and were hindering stator expansion. After the bushings were machined and the holes elongated, the stator roundness immediately improved although there was still some degree of ovalness.

The high vibration at the generator guide bearing appeared to originate from the rotor roundness and concentricity. Since the rotor has a small concentricity, balancing the unit was recommended.

This case demonstrates the importance of undertaking comprehensive tests and analysis upon commissioning of a new or refurbished machine. Repeating the process in subsequent years and comparing and trending parameter evolution, dynamic behaviour and mechanical condition is valuable. For example, after the first set of test results from RH Saunders dam, the machine was considered reliable in the short term. However, it was only through further testing at later dates that other problems were detected and rectified. Such testing can provide information which is invaluable for discussion with manufacturers, enforcing warranty terms and implementing condition based inspections.

For more information visit www.vibrosystm.com

| ZOOM system |

|

The ZOOM is a zero outage on-line measuring system, designed specifically to monitor hydrogenerating machines thoroughly. Its capabilities include the tool to trend parameters, diagnose anomalies, and prevent failures in order to improve machine efficiency and reliability by reducing maintenance activities, downtime and related costs, says VibrosystM. * Shaft displacement and vibration. Its open architecture provides configuration flexibility to suit machine or customer monitoring needs, from vital signs (8 to 16 parameters) to extensive (24 to 64 parameters) monitoring, and integration of existing instrumentation from any source. According to VibrosystM, this makes it a very easy and affordable tool to implement. |