There is growing interest in supercritical coal plant technology in the USA – as embodied in Council Bluffs Energy Centre unit 4

Construction is underway at MidAmerican Energy’s 790 MWe Council Bluffs Energy Centre (CBEC) unit 4, the first PF (pulverised fuel) supercritical coal plant to be built in the USA for many years. This unit, located in Iowa, also has the distinction of being the first plant in the USA – and perhaps anywhere – to have a mercury limit specifically noted in its air pollution permit, namely 0.0000017 lb/MMBtu.

Time for a reappraisal

The Americans embraced supercritical coal plant technology early on, and indeed pioneered the concept in the 1950s. Many supercritical coal fired plants were built in the USA in the 60s and 70s. But technical problems experienced at that time (see table, next page), including materials degradation and the need for overly complex operating procedures, gave supercritical a bad image in the USA, from which it is only now recovering.

In fact many of these early US supercritical plants, of which there is estimated to be a population of about 170, are now achieving good performance, with average availabilities similar to those of subcritical plants.

But more important, the technology has moved on dramatically over the intervening years, thanks to perseverance in Europe and elsewhere, notably Japan, Korea, Canada (where Genesee 3 is due to start up shortly, the first new supercritical plant in North America for a very long time), China, India and Australia.

The supercritical technology now available, benefiting from advances in boiler design, metallurgy and control systems, for example, presents a much more attractive proposition to US power plant developers, provided they can be persuaded to look at it without preconceptions, of course.

MidAmerican analysed the options very carefully and concluded that supercritical was now a well proven technology and undoubtedly the way to go, finding that “under most assumptions used a supercritical unit was more economical and environmentally responsible than subcritical units.”

Among the considerations: supercritical technology is more efficient and produces significantly less emissions (CO2, NOx, SO2, Hg), providing, for example, a good hedge against any future CO2 tax regimes; per unit of electricity produced there is less coal to mine, transport and handle, with correspondingly less ash; water is used more effectively, with less needed for cooling tower makeup; and urea and lime consumption is reduced.

MidAmerican’s Steven Brewer, general manager of CBEC and project manager of unit 4, describing his company’s plans at the Electric Power 2004 conference in Baltimore (30 March-1 April), went so far as to say that, for plants of 500 MW or more, he couldn’t believe anyone would buy subcritical anymore. “I’d be shocked if anyone was still to consider subcritical in the CBEC 4 size range”, he told Modern Power Systems. In the CBEC 4 case, “It was clearly the right thing to do,” he said.

However, for the moment, CBEC 4, due to enter commercial operation in June 2007, remains the only supercritical plant actually under construction in the USA, although it is likely to be joined by two 615 MW supercritical PF coal projects in Wisconsin in the not too distant future. These two units, proposed by We Energies, a subsidiary of Wisconsin Energy Corporation, as part of its Power the Future programme, were approved by the Public Service Commission of Wisconsin in November. They are an expansion of the existing Oak Creek power plant and are due to go on line in 2009 and 2010. The approval of the two units, with a total construction cost of $2.15 billion, cited the lower air emissions and higher efficiency of the supercritical technology, and was given subject to the implementation of programmes “to capture 55 MW of cost-effective energy efficiency by 2008.” (Interestingly, a 600 MW IGCC plant also proposed by We Energies was not approved, on grounds of cost and “technology concerns”.)

While planned new generating capacity in the United States is predominantly natural gas, there are about 94 proposals out there for new coal-fired power plants, at least according to the most recent listing (February 2004) compiled by the US Department of Energy’s National Energy Technology Laboratory, which tracks these things. This amounts to 62 GW of planned new coal generating capacity. However, as NETL cautions, many of these units will not get built, noting that, of 500 GW of newly planned power plant capacity announced in 2003, 91 GW have already been scrapped or delayed.

Also not yet publicly known for most of these proposed projects is the choice of technology. But with the precedent of CBEC and Oak Creek, the outlook for supercritical PF coal technology in the USA must now be better than for some considerable time.

CBEC4 – the basics

Council Bluffs Energy Center unit 4, with steam conditions of 3690psig/1050°F/1100°F (25.3 MPa/566°C/593°C), will use low sulphur, Powder River Basin, coal, with HHV of 8400 Btu/lb, consuming 3 million tons per year.

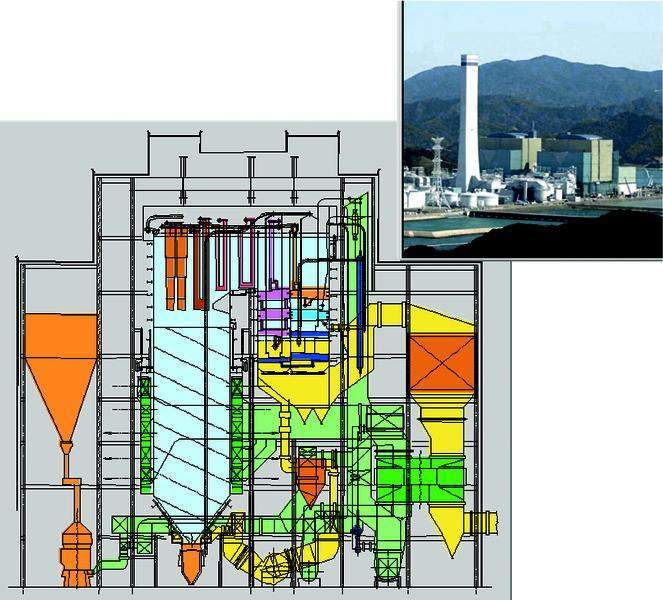

At the heart of the new plant, which has an estimated project cost of $1.2 billion, is a once-through sliding pressure Benson boiler, supplied by Babcock-Hitachi, a division of Hitachi, Ltd. The Tachibanawan 2 plant, which boasts the highest steam conditions in Japan, is the reference plant, although it uses bituminous coal, which affects the rating etc. The sliding pressure Benson boiler design fully addresses many of the issues that dogged early supercritical plants in the USA. It promises high reliability, flexible and easy operation, high efficiency from partial to full load and ease of maintenance, says the supplier.

There are three existing units on the CBEC site: unit 1, 43 MWe, completed 1954; unit 2, 88 MWe, completed 1958; and unit 3, 690 MWe, completed 1979. The new unit will require the following additions to the transmission infrastructure:123 miles of 345 kV transmission line; two new 345 kV to 161 kV substations; and two new 161 kV transmission lines (23 miles).

Emissions control provisions include lime spray drier FGD, low NOx burners. overfire air and SCR for NOx, pulse jet fabric filter for particulates and activated carbon injection for additional Hg control. As well as the mercury limit, already noted, the other major air permit limits are: NOx, 0.07 lb/MMBtu; SO2, 0.10 lb/MMBtu; and opacity, 5%. The guarantee levels are 0.05 lb/MMBtu for NOx and 0.08 lb/MMBtu for SOx, with urea consumption less than 865 lb/h, minimum load 35%.

Milestone dates were: July 2001 – project inception; Nov 2001 – location finalised; March 2002 – RFP for EPC contract issued; Feb 2003 – contract signed; Sept 2003 – notice to proceed issued.

Mitsui & Co Energy Development, Inc is prime contractor, while Hitachi is responsible for the entire EPC scope. It is in fact Hitachi’s first thermal plant EPC project in the USA. In turn S&L is providing engineering as subcontractor to Hitachi, while Kvaerner Songer is general constructor, again under contract to Hitachi, which is also supplying steam turbine, generator plus much other plant equipment.

In addition to MidAmerican Energy, a wide range of Iowa and some Nebraskan utilities also have a stake in Council Bluffs Energy Center unit 4: Central Iowa Power Co-op; New Hampton; Alta; Pella; Cedar Falls; Spencer; Eldridge; Sumner; Lincoln (Nebraska); Waverly; Montezuma; West Bend; Corn Belt Power Co-op; and Municipal Energy Agency of Nebraska.

As well as coal, MidAmerican’s generation portfolio includes renewables, nuclear, hydro, natural gas and oil. It is has recently announced plans to construct 310 MW of wind in central Iowa. But it sees coal as “the backbone of MidAmerican’s and the nation’s electric generation because it is plentiful, economical and secure.”

Genesee 3 gets ready

Meanwhile in Alberta, Canada, south west of Edmonton, the 495 MWe (gross) Genesee 3 unit – a joint venture of TransAlta and EPCOR – is due to enter commercial operation in winter 2004/5. With steam conditions of 25 MPa/570°C/568°C, this is also using a Babcock-Hitachi supercritical sliding pressure once-through Benson boiler.