The two new power reactors to be constructed at Bulgaria’s Belene site (see MPS, December 2006, p 37) will employ an advanced version of the VVER-1000, a 1000 MWe class pressurised water reactor (PWR) design developed in Russia.

Called the V-466 this advanced version of the VVER-1000 builds on the extensive experience that has now been amassed with the series-produced V-320 version of the VVER-1000, developed by Russian PWR design organisation Gidropress.

Successful operation of some 25 units of the VVER-1000 V-320 type, in Russia, Ukraine, Bulgaria (at the Kozloduy plant) and the Czech Republic, has confirmed the validity of engineering parameters inherent in the original design and the reliability and operational safety of both systems and components. Thus far, type V-320 reactors have recorded more than 400 reactor-years of operation.

As long ago as 1977, Atomenergoproekt of St Petersburg, Podolsk based Gidropress and Finnish utility IVO (now Fortum) began development of a new nuclear power plant design based on the VVER-1000 V-320. In 1991 these Russian organisations offered a plant of this design in a bidding process to construct Finland’s fifth nuclear reactor, at Loviisa – shortly afterwards abandoned in the wake of a decision by the Finnish government.

Further improvements to the VVER-1000 V-320 resulted in the creation of the V-428 version of the VVER-1000. A power plant with two reactors of this type has been constructed in China, at Tianwan (pictured below), and is due to enter commercial operation shortly.

The V-428 version incorporates evolutionary measures to enhance safety, but preserves to the maximum extent possible the basic V-320 layout and equipment configuration. The V-428 design development effort basically had the following goals:

• to take fully onboard international thinking about how to improve safety in large PWRs;

• to attain, or improve upon, the latest safety standards used in power reactor safety design worldwide;

• to make maximum use

of operationally proven technologies and equipment; and

• to improve economics, including reduction in construction costs.

Among the specific improvements incorporated in the V-428 were the following:

• changes to core nuclear physics parameters;

• measures to assure a negative reactivity coefficient at all times;

• implementation of the four-train principle of safety systems redundancy;

• use of upgraded systems for control and equipment diagnostics;

• adoption of a core melt localisation device;

• adoption of double-wall containment;

• use of a new reactor coolant pump design with water lubricated bearing;

• use of entirely digital I&C system;

• reduction in the number of pumps, valves etc;

• optimisation of building layout;

• modernisation of post-accident monitoring ;

• measures to considerably decrease the amount of liquid radioactive waste treatment;

• measures to improve earthquake resistance; and

• full adoption of the “leak before break” concept.

The V-466, as selected for Belene, represents the next stage in the evolution of of the VVER-1000, and is essentially an advanced version of the V-428, in which International Atomic Energy Agency recommendations, along with the latest Russian and international standards, were taken into consideration. This resulted in the following additional design goals:

• increase in the lifetime of main equipment

(ie basically the pressure vessel) to 60 years;

• increase in maximum average fuel burn up to 55 MW per day/kg U;

• reduction of outage time and increase in availability (unit capability factor); and

• improved load following capability and manoeuvrability.

Responding to world trends in nuclear safety design practice, additional passive safety systems were introduced into the new design. The updating of the design was done by Atomenergoproekt Moscow and it was this latest evolution of the VVER-1000, the V-466, that was offered in the bidding for Bulgaria’s Belene project.

Features of the V-466 design

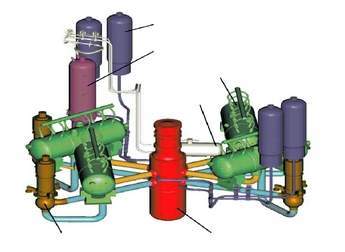

The V-466 provides an installed capacity of 1060 MWe and is designed for both baseload and load following. The reactor is designed to operate for 7900 hours per year at nominal capacity, with refuelling once per year. The primary circuit comprises the reactor, the pressure compensation system and four circulation loops, each including a horizontal type steam generator, a reactor coolant pump and a main circulation pipeline of 850 mm diameter. The reactor main data are given in Table 1. Average enrichment of the uranium oxide fuel is 4.3% (by weight).

The steam generators give up their heat to the water flowing in the secondary circuit, which consists of the steam generating part of the steam generators, main steam pipelines, turbine plant, auxiliary and service systems, deaeration equipment, and feedwater heating and supply to steam generators and blowdown systems.

The turbine plant consists of a steam turbine and a generator mounted on the same foundation. The turbine is equipped with condenser, recuperative water heating plant, and separators/steam superheaters. It also has unregulated steam extraction for the heaters of the recuperation system and for power plant in-house needs.

Safety assurance

The main task of nuclear plant safety assurance is the protection of operating personnel, the public and the environment from unacceptable radiation exposure under all operating conditions, including design basis and beyond design basis accidents. In the V-466 this is achieved through the implementation of safety systems comprising:

• a double containment with an intermediate shell;

• a passive leakage filtration system;

• a system of hydrogen removal based on passive recombiners;

• a sprinkler system to lower the containment pressure during accidents; and

• a device for core melt (corium) localisation.

These measures, for all practical purposes, eliminate the possibility of exceeding the maximum emergency release for beyond design basis accidents, including severe accidents with complete nuclear fuel melting. High reliability of safety functions is ensured by implementation of mutually redundant passive and active safety systems, and also through the use of diversity.

Passive safety systems incorporated in the V-466 include:

• a passive system for heat removal from the steam generators;

• a system of prompt boron injection into the primary circuit;

• hydraulic accumulators incorporated in the reactor emergency cooling system;

• intermediate shell filtration system;

• the corium localisation device.

Corium localisation device

The corium localisation device is designed to perform the following functions in the event of a severe accident with fuel melting:

• retention of solid and liquid fragments of the damaged core and also parts of the reactor pressure vessel;

• assurance of cooling water supply to corium as well as steam removal;

• transfer of heat to cooling water;

• retention of the reactor pressure vessel bottom should it become detached; and

• minimisation of release of radioactive substances and hydrogen into the containment inner space.

The corium localisation device is designed to perform these functions with minimum control effort required of the plant operating staff. The corium can be localised and cooled indefinitely. After an accident and under complete plant blackout conditions, there is sufficient reserve of water available in the containment sump to assure cooling of the corium for 24 hours. The core can be reliably retained for longer periods once replenishment of the water reserve from external sources has been established.

Protection against external hazards

The reactor is protected against external hazards by the outer shell of the double containment. The inner part of the containment is made of prestressed reinforced concrete with stainless steel cladding on the inside. The outer shell, which does not use prestressing, is able to withstand:

• a seismic load with maximum horizontal acceleration of 0.2 g;

• wind load;

• aeroplane crashes;

• shock waves; and

• snow load.

Tianwan, China, where two reactors of the VVER-1000 V-428 type are due to enter operation shortly.

The V-466 units to be deployed at Belene in Bulgaria represent the next step in the evolution of the VVER-1000 Basic layout of the VVER-1000/V-466 primary circuit Safety systems of the V-466 Key:

1 – Bottom plate; 4 – Basket;

2 – Cantilever truss; 5 – Pressure vessel;

3 – Service area; 6 – Concrete pit

Details of the corium localisation device employed in the V-466 Fuel of the type to be employed in the Belene

V-466 reactors. Russian supplier TVEL is offering fuel of the advanced TVSA type, with a longer campaign time (320 effective days compared with 295 days for the Kozloduy (Bulgaria) and Ukrainian plants), inc