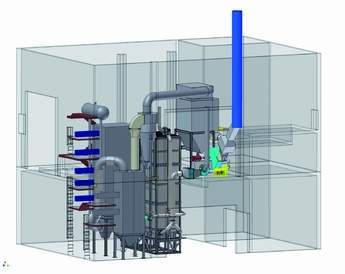

The Siemens Industrial Solutions and Services Group has received an order from Zweckverband Restmüllheizkraftwerk Böblingen (RBB) of Baden-Württemberg, Germany, to supply a 6 MWt “Reject Power” CHP station. The Reject Power plant, consisting of combustion chamber, waste heat recovery steam generator, flue gas cleaning system (including stack), and the electrical and control equipment, is designed to make use of low grade “reject” material as fuel, which otherwise would have to be treated as waste material. The plant makes use of a “spinning wheel” fuel injection system, which allows the use of combustible materials with high water content. The plant will burn what are called sifting residues resulting from “chip hogging”, a process in which tree clearance and shrubbery cuttings collected in the private sector are employed as input material for making wood chips. Such chips are used in such applications as fuel for heating and power stations or for wood stoves.

Conventional wood-chip heating installations cannot handle sifting residues and burning them in waste incineration plants is uneconomic.

The new Reject Power unit is designed to burn around 18000 tonnes of sifting residue annually and will generate 6.4 tonnes of steam an hour for power generation via steam turbine and will also be used for district heat supply. The order is worth around 3.5 million euros and handover of the installation is scheduled for July 2008.

RBB is an association of different cities around Böblingen which aims to operate the waste wood incineration plant to produce district heat and electricity.

3D image of a Siemens Reject Power installation. Schematic of the “spinning wheel” fuel injection system (also called a “directional throw conveyor”)