A significant component of India’s nationwide transmission network has fallen into place with the completion and bedding in of the Purnea and Gorakhpur high capacity East-North Interconnector II, a turnkey FACTS project reckoned to be the world’s largest such installation with series compensation

Progressive worldwide urbanisation, as well as the trend towards mega-cities with more than 10 million inhabitants, is creating many new challenges. In every country of the world, according to UN statistics, the economic influences radiating from large cities provide more than half of the gross domestic product of that country. One of the most important factors for the economic dynamics of mega-cities is an effective infrastructure. The basis for this infrastructure is constituted in a reliable and efficient power supply.

An important development in the power supply for such cities is the relocation, for environmental reasons, of power generation from city centres out into the surrounding countryside, sometimes at considerable distance. Even more significantly, sufficient power to cover increasing demand must be delivered from additional sources that are normally located far away from the load centres. This is why the transmission of large power blocks over long distances is becoming increasingly more important. Furthermore, efficiency and reliability of supply play an important role in every planning process, particularly in the face of increasing energy prices and almost incalculable safety risks during power blackouts.

Figure 1. Purnea substation

This is certainly the case in India. An increasing demand for electricity and a growing awareness of the need for reliable power supplies, for the fast developing mega-cities in particular, have prompted Powergrid (the utility company that operates India’s high voltage transmission networks) not only to continue with its overall transmission plan, but also to strengthen its networks with a technology known as ‘flexible AC transmission system’, or FACTS.

This transmission enhancement plan was devised by Powergrid, and its implemention got under way, to establish an integrated national grid and to support an additional programme for new generation capacity. Today‘s programme of 9 500 MW inter-regional power transfer capacity is expected to be increased to 30 000 MW by 2012.

With the help of its 400 kV series compensation system (SCS), which is the preferred FACTS solutions for the Purnea and Gorakhpur substation projects (Figure 1), Power Grid Corporation of India is taking steps to enhance its east to west power transfer. The power generated in the Tala hydroelectric power plant, located in Bhutan, is transmitted via a newly built 400 kV double-circuit transmission line to Gorakhpur substation. There, the line is connected to the existing 400 kV network, and feeds into the northern industrialised region around the capital New Delhi. Because of this interconnection the north-east of India can also profit from economic hydro power.

Figure 2. Line diagram of the Purnea / Gorakhpur substations with FSC and TCSC

Benefits of SCS

Series compensation is the ideal ‘low cost’ solution for bulk-power long distance AC transmission. Series compensation can also be applied very effectively in meshed systems for balancing the load flow by means of ‘load displacement’.

The principle of series compensation consists in using a series capacitor which compensates the

line reactance, so the line becomes virtually shorter. Because of this the transmission angle is reduced and system stability is increased. This increases the transmission capacity of the existing line without having to install new conductors.

The simplest form of series compensation is known as fixed series compensation (FSC), the main benefit of which is to allow an increase in transmission capacity. The more sophisticated TCSC (thyristor controlled series compensation) is deployed if fast control of the line impedance is required, for load-flow control, and for damping power oscillations. It also has the benefit of allowing mitigation of subsynchronous resonances (see below).

Designing series compensation

Figure 2 shows in a single-line diagram the layout of the Purnea and Gorakhpur FSC and TCSC combination.

FSC

A segment of a fixed series capacitor bank (FSC) consists of a capacitor bank and a MOV (metal oxide varistor) assembly, connected in parallel. It also includes a spark gap which is used to protect capacitors and MOV against overvoltages which occur during and after faults in the transmission system.

A damping circuit is connected in series with the triggered spark gap and the bypass-switch in order to reduce component stress during transient discharge of the capacitor. The bypass-switch is connected in parallel to the spark gap to provide current commutation for the time when the current capability of the MOV or the spark gap is exceeded during AC faults.

In the case of high short-circuit currents caused by faults on the AC-line to which the capacitor bank is connected, the spark gap and the bypass-switch will be triggered in order to protect the capacitor and the MOV from overload. A fault on other lines, for example behind the neighbouring buses, usually produces lower currents in the series capacitor, and the bypass devices do not need to be operated.

TCSC

The main components of the TCSC segment are also shown in Figure 2. The capacitor is protected against overvoltages by the MOV. The MOV is designed to withstand stresses such as these. The operation strategy for the bypass devices is the same as for the FSC.

The thyristor valve branch with the reactor is connected in parallel to the capacitor. The impedance of the parallel L-C circuit can be varied by means of firing the thyristor valve. In case of AC-line faults the thyristor valve can be blocked in order to reduce the capacitive impedance and consequently the fault current.

Basically, the thyristor valve could have been used to provide the bypass function alone, without the spark gap. For this project, however, it was decided to use a separate triggered spark gap as a fast protecting device, because of very high thermal stress for the thyristors caused by extremely high fault currents. This enables immediate operation of the thyrister valve in the full dynamic range, for example for power oscillations damping which is normally required after fault clearing in order to stabilise the system.

The capacitor discharge current is limited by means of the bypass damping circuit in the same way as in the case of the FSC.

The TCSC offers the opportunity of power oscillation damping and power-flow control via the controllable impedance. The thyristor controlled reactor branch is formed by a reactor and a thyristor valve. The thyristor valve is made-up of a number of series connected thyristors, two branches of which are connected in anti-parallel. The valve is located in a housing on the platform.

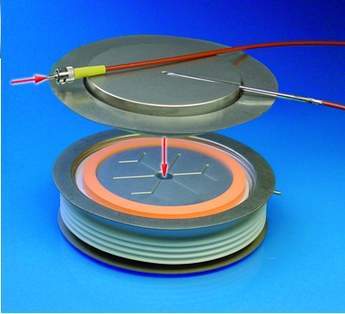

For FACTS applications, thyristors are a key element in the control of passive components.

LTT (direct light-triggered thyristor) valves with wafer-integrated overvoltage protection for HVDC and FACTS (Figure 3) are a product unique to Siemens. The system of direct light triggering fires the thyristors with a light pulse. The light pulse generated at ground potential is guided by fibre optics directly from the valve control to the thyristor gate.

Light-triggered thyristors offer significant benefits compared to conventional electrically triggered thyristors, for example they require fewer electronic components to be at high potential and give a corresponding increase in reliability.

The thyristor valve is fired at a firing angle calculated according to control requirements, eg impedance control or current control. With impedance control the transmission angle of the line can be influenced and current control determines the load flow. In normal steady-state operation the TCSC impedance is set to a value which is 1.2 times the capacitor impedance. The dynamic range covers 1-3 pu. During remote faults in the system the thyristor valve continues firing. At severe disturbances the thyristor valve is blocked. After fault clearing, the TCSC is ready to fulfill its main purpose, ie power oscillation damping with its full capacitive operating range.

Studies

In the run-up to the basic design specifications the following studies were carried out: a detailed power oscillation damping (POD) study and a subsynchronous resonance (SSR) study, as well as calculations necessary for defining the control parameters.

Figure 3. Thyristor valve with direct-light triggered 100 mm thyristrors with integrated break-over protection. Direct-light triggering is said to have advantages in that it requires fewer components, less wiring, and has inbuilt over-voltage protection.

Power oscillation damping

Studies showed that power oscillations occur between the two interconnected systems after severe disturbances, for example that due to a loss of generation in one of the two systems. A TCSC was found to be the optimal solution to damp these oscillations.

For power oscillation damping, the full capacitive operating range can be used, as described above. The benefits of the damping function are shown in Figure 4.

Subsynchronous resonances (SSR)

The degree of compensation of a line has to be decided according to the system conditions, eg the line length and stability requirements. However, the design also has to take into account the fact that series compensated lines can excite torsional oscillations of generators with long shafts. These subsynchronous resonances (SSR), as they are termed, can pose a severe problem for large thermal units, for example steam turbines, combined cycle turbines, large gas turbines, and especially for nuclear units. Under certain conditions, generator shafts as long as these can be damaged or even destroyed.

Depending on the construction of the generator, the turbine and the excitation system, typical resonance frequencies of generator turbo set shafts are between 10 and 45 Hz with very low damping.

Using only fixed series compensation without TCSC, high degrees of compensation in transmission lines can produce interaction of the electric resonances of the system with the mechanical torsional frequencies of the generator shaft. A small disturbance in the electric torque can excite relatively high amplitudes of torsional oscillations, when the corresponding electric frequency matches one of the mechanical oscillation modes of the generator shaft. An electric torque, produced by the LC circuit of line impedance and series capacitor, may act as a negative damping to torsional oscillations when the LC resonance frequency interacts with the generator shaft. The LC resonance frequency is of subsynchronous nature, as the compensation degree is always less than 100 %.

A much better effect is produced using the TCSC for SSR mitigation by changing the apparent impedance of the TCSC according to torsional oscillation with a suitable phase of the oscillating electric torque. The passive mitigation effect of the TCSC depends on the resonance frequency, the firing angle, the line configuration, as well as on other system parameters, such as the short-circuit power of the system. All these influencing parameters were covered in the SSR study.

Figure 4. Power oscillation damping

TCSC Control

The closed-loop control (CLC), the open-loop control (OLC) and the redundant protection system are fully digitalised with a Siemens Win TDC signal processor system. A number of signals are measured on the platform at high voltage potential. After conversion into optical pulses, the signals are sent to ground potential via fibre optic links, and they are then reconverted into values in a digital format. The auxiliary power supply for the conversion on platform is sent via a second fibre optic link.

The main task of the closed loop control system is to determine the firing angle alpha that defines the TCSC-impedance. Normally, the TCSC operates in impedance mode, where the TCSC provides an impedance as required (reference value). As soon as power oscillation along the line is detected by means of line current measurement, the control system switches over to the power oscillation damping mode. The trigger set generates the firing pulses according to the firing angle which is the input value. The correct timing of the firing pulses is continuously synchronised with the AC system frequency through the line current. Digital filtering is used to determine the reference point for each firing pulse. This is also the case under system conditions with non-sinusoidal waveforms of line current.

The control and protection of the TCSC detects the eventual overload of all components, and takes into account overload requirements. The protection can respond by blocking the thyristor valves, by triggering the spark gap (fast bypass) and by closing the bypass-switch, depending on the type, severity and duration of the fault. After a single-phase fault in the system, it is foreseen that only the faulty phase is opened by the line protection, and it will be re-closed after about one second. In this case, only one phase element of the TCSC is bypassed, to provide the highest possible stabilisation of the system. Only when the line is opened in all three phases is the TCSC also bypassed in all three phases.

The value of a configuration with the FSC plus the TCSC is that it offers significant benefits for transmission. The fixed series capacitors (FSC) compensate 40 % of the line impedance, reduce transmission losses and, consequently, increase power transfer. They also improve steady-state and dynamic-stability of the system.

Thyristor controlled series capacitors constitute the solution which provides transient stability of the increasing power transfer. Each of the TCSCs is designed to compensate 6 % of the line impedance during steady-state operation, and to vary the impedance in transient conditions in a range between 1-3 pu. This enables the damping of power oscillations which may occur during and after system disturbances.

This means that with the advanced control features of the TCSC, separation of the two interconnected systems can be avoided. Resynchronisation of the two systems would be of great technical complexity, which is why avoiding separation is of vital interest for transmission.

Project overview

Siemens received the order for the FSC/TCSC at the end of May 2004, and a project team with members from India and Germany was assigned to the job. Reactors, capacitor banks, MOV, circuit breakers, spark gaps, thyristor valves and the control system for the project, which has been financed by the World Bank, were supplied by Siemens Germany. All other equipment and activities, which included platforms, civil works, installation and commissioning were provided by Siemens India.

Gorakhpur substation

Civil works

The Purnea-Muzafarpur and Muzafarpur-Gorakhpur double-circuit transmission line has been constructed to carry power from the eastern to the northern part of the country. Power Grid Corporation of India Ltd (Powergrid) with consultancy Government of India Enterprise established the 475 km long, 420 kV line in two sections 242 km and 233 km long. As a part of civil works, in the floodplain area between Purnea in Bihar State and Gorakhpur in the State of Uttar Pradesh (some 50 km north of the Ganges) piling was necessary to stabilise the foundations.

Erection and commissioning

Both transmission lines and the FACTS equipment were put into operation in 2006. Since then they have been providing a reliable transmission corridor for delivering power from the eastern part of India to the load centres in the north of the country.