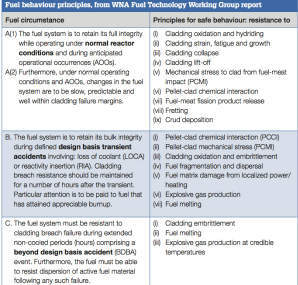

Determining the overall safety level for a new nuclear fuel is not trivial because it involves balancing a host of attributes in several operating scenarios. Currently, there is no focussed, peer-reviewed guidance to help perform such assessments. The work described here, based on a report by the World Nuclear Association’s Fuel Technology Working Group, is intended to be a starting point for formal safety assessment. By Julian Kelly

Physical and/or chemical changes are inflicted on fuel because of extra energy deposited in the fuel as a result of a reactivity insertion accident (RIA) or loss of coolant accident (LOCA). In considering detrimental chemical changes that may be inflicted on a fuel component during a transient/accident, the occurrence and effect of these during the event is not of concern because they occur more slowly than the accident itself. However, they become very important when considering the safety credentials for a fuel that survives such an accident, since it needs to be safely stored and managed over long periods.

Cladding integrity can be threatened by chemical attack during power ramps and transients, as well as during normal operation.In particular, corrosion by aggressive species (most notably iodine) at stress-induced cracks can cause rapid cladding breach and fuel failure. Certain fuel technologies help minimize this threat, either by better fission gas retention within the fuel material and/or by using cladding material that is more resistant to specific SCC attack.

In pellet-based fuels, PCMI can pose a serious threat to fuel integrity during accident conditions in which large and rapid temperature rises cause pellets and gas to expand and produce gas, both of which apply large forces on the cladding wall. This damage mechanism is one of the most important to understand in a RIA scenario since it can be a limiting fuel design factor. Consideration of the vulnerability of a new fuel to PCMI in accident conditions needs to be more rigorous than when the fuel operates in normal/AOO conditions. In the more severe RIA event it is not only high-burnup ‘rim structure’ fuel but also other lower-burnup fuel that can inflict damaging force on the cladding wall. A new fuel that is capable of demonstrating strong resistance to PCMI failure through to high burnup levels can claim considerable safety margin credit, according to ‘A Framework for Assessing the Safety of New Nuclear Fuels’, the report upon which this article is based.

In accident scenarios, there are distinct oxidative degradation pathways to assess, especially if the new fuel uses a zirconium alloy cladding. The oxidation of a (metal) cladding can produce hydrogen (H2) which can dissolve in the metal while at elevated temperature; this not only reduces cladding strength, but also when the temperature drops the hydrogen may form metal-hydride particles that precipitate within the metal, causing it to become brittle and prone to fracture and failure. Both oxidation rate (H2 production) and H2 dissolution increase with temperature; hence the licence limits the temperature that a zirconium-clad fuel can attain, both during a LOCA, and during a non- LOCA power transient event. Degradation due to high temperature oxidation and subsequent embrittlement is of significance well after a RIA event; a new fuel surviving a RIA will need to be safely stored for long periods during which its strength and/or integrity needs to be assured. Fuels can acquire resistance to this effect by using cladding material that offers any or all of: (i) reduced potential for reacting with water to produce H2, (ii) reduced solubility of H2 in the cladding material, or (iii) reduced potential for forming hydride phases. Greater mechanical strength cladding also lends resistance.

High burnup fuel has a tendency to fragment, particularly around the pellet rim. If this occurs, fuel pieces can relocate to areas where cladding lifts away from the fuel, as may occur during a LOCA or RIA. In a subsequent event where the cladding ruptures, fragmented fuel can be dispersed, potentially worsening radiological consequences and even inducing a steam explosion.

A low thermo-chemical potential for producing hydrogen or other explosive gases is a highly desirable feature for any new fuel type. Safety margin credit can be claimed for fuels using cladding material that is less inclined (than zirconium) to chemically react to produce H2. Particular attention should be paid to exothermic reaction pathways with steam at high temperature, since these lead to positive- feedback energy production loops during such an accident.

Fuel safety criteria specify that no part of a fuel can melt in the event of a power transient (or during normal operation). This is a conservative rule since it has been established that localized melting within a fuel pellet does not necessarily cause overall fuel failure. Nevertheless, the no-melt criterion remains an appropriate regulatory guideline since it rules out overheated zones, molten fuel-to-cladding contact, and piercing risk. For fuels with non- homogeneous fuel-meat, that is, those with appreciable ‘granularity’ and/or two distinct phases, a safety assessment should take into account whether partial melting of distinct phases may be possible within the fuel-meat. A higher margin to melting can be derived from a higher melting point for the fuel-meat, and/ or a lower operating temperature for the fuel in normal and AOO conditions (stemming mainly from higher thermal conductivity).

Behaviour: beyond design basis

A new nuclear fuel system must manifest a satisfactory response during a beyond design basis accident (BDBA) scenario. Such accidents are not defined explicitly, but can be regarded as rare, extreme cases of a LOCA (or RIA + LOCA) event in which the fuel experiences high LOCA-type temperatures for an extended period — longer than a few hours. In such severe conditions a fuel can be expected to degrade. Its BDBA safety performance should be assessed according to: (i) the time it can resist failure,

(ii) the amount of activity it is likely to release upon failure in the extended LOCA conditions, and (iii) the mechanistic nature of the failure and whether this leads to or contributes to the dispersal of activity (for example, if coupled to melting or gas detonation processes). Assessing the BDBA safety performance for a new nuclear fuel requires the use of credible time- temperature accident progression predictions that have been generated for the particular fuel / reactor system.

Cladding embrittlement is the result of extensive oxidation of metallic (for example, Zircaloy) cladding materials at high temperature. The metal cladding picks up hydrogen while at elevated temperature and hydrides precipitate when the temperature drops, resulting in a loss of strength.

Fuel systems (including cladding) with a higher melting point and/or higher thermal conductivity are inherently advantageous in terms of the time before parts of the fuel will melt after an extreme/beyond design basis LOCA.

A low thermo-chemical potential for producing hydrogen or other combustible gas has even higher significance in the BDBA scenario than normal conditions due to the large volumes of hydrogen that can be rapidly generated in such conditions. Safety margin credit can be claimed for fuels using cladding material that has a limited tendency to react to produce gases that have the potential to cause explosive reactions such as carbon monoxide and hydrogen.

Behaviour: short-term storage

A new nuclear fuel system must behave in a safe and predictable manner in all conditions in which it is to be stored and transported after fuel is discharged from the reactor. Consideration should be given to both wet and dry storage conditions and also to the impact on or by handling operations therein.

A fuel system’s mechanical strength must be able to resist creep strain as a result of rod internal pressure during the first decades of dry storage. During this period the residual decay heat production is still high and can result in high fuel rod temperatures which may facilitate cladding creep mechanisms and increase the overall creep rate. A fuel technology developer should assess creep strain vulnerability at the time of discharge and also whether this vulnerability changes over any extended storage period, factoring in the heat-transfer capabilities of the storage system.

A key cause for the weakening of used fuel zirconium alloy cladding over long periods is the formation of microscopic hydride phases. These hydrides can lead to excessive embrittlement directly (such that the cladding can fail during handling) and/ or they may cause a damage phenomenon called delayed hydride cracking. In the latter damage pathway, which is of concern mainly in dry storage conditions, existing circumferential hydrides dissolve at the start of dry storage (or during any prior vacuum drying) when clad temperatures are high, then re-precipitate as radial hydrides later when the decay heat, and hence clad temperatures, falls as storage progresses. This is only risky when the clad hoop stresses exceed a certain level at the time of re-precipitation; otherwise the hydrides tend to re-precipitate in a circumferential direction, in which case they are no more damaging than the original hydrides formed during irradiation. A demonstrated resistance to this or any other type of chemically-driven degradation is a positive safety attribute for any new fuel type.

Pellet-clad gap source terms are not normally regarded as being operational safety criteria; however, for spent nuclear fuel in extended storage it is important to consider the quantity of each of the fission nuclides that are most easily released from the fuel matrix to the remaining internal space of the fuel rod. In oxide fuel, it is volatile/ mobile caesium and iodine isotopes that are of key concern (despite having a high activity and yield, the vast majority of strontium is retained within the fuel matrix and so does not contribute significantly to the gap source term). Estimation of nuclide inventories should be made at various points

in time after discharge (up to ~50 years) so that these can be assessed and/or compared when fuel movements are foreseen.

Comparison of this source term between different fuel types at the end of their service lifetimes is of considerable interest to regulators, since it is a determining factor in the threat posed to fuel integrity over long storage periods. A lower gap inventory of caesium and iodine will be considered as a safety-positive feature for a new fuel.

Behaviour: long-term storage

To properly assess the viability of permanent disposal of a fuel in a geological repository, specific consideration needs to be made of (i) the inventory of spent fuel per unit of energy generated, (ii) the mass fractions of each radionuclide (including fission products, actinides, and activation products), (iii) the instant release fraction of each radionuclide, (iv) the fuel matrix dissolution rate, (v) transport of the radionuclides in groundwater, and (vi) the dose uptake of each of the various uptake mechanisms for each of the released nuclides. The nuclides I-129, Cs-135, Cl-36, Ni-59 and C-14 are particularly important, but new fuel types may differ in these ‘key’ isotopes from a dose uptake point of view.

The radiotoxicity of the suite of radioisotopes released upon a postulated penetration of a spent fuel canister by groundwater can be expressed by the metric of penetration radiotoxicity. It is derived by assessing (i) to (iii) above. It includes consideration of an ‘instant release fraction’ (IRF) which typically includes contributions from the rod free volume, the cladding (pessimistically assumed to have corroded away before spent fuel canister penetration) and fuel grain boundaries. A new fuel with a high fission product retention capability will have a lower penetration toxicity, which counts as a safety merit. In principle, a more robust cladding could also be counted towards a lower penetration toxicity. The longer- term release of radionuclides (in particular the actinides) occurs by fuel matrix dissolution in groundwater, so a more insoluble fuel matrix can serve as a separate safety credential for new nuclear fuel.

Other considerations

Nuclear fuel operates in a severe environment and sustains extensive structural damage to material lattices due to the impact of high energy particles and fission fragments. Nevertheless, there is a competing reverse process in which the particle flux causes a degree of self- annealing and repair of some lattice defects. Self-annealing effects are temperature- and flux-dependent, but it is not possible to reliably predict their extent. Different fuel materials are expected to manifest different levels of self- healing and it may be possible to claim a safety margin benefit if this can be demonstrated.

A new fuel design must be compatible with current fuel types since it will generally be phased in over a few core reloads. A compatibility assessment needs to address neutronic aspects, thermal-hydraulic aspects and chemical compatibility.

Nuclear fuel is deemed to have failed if its cladding becomes ruptured and radioactive material leaks into the coolant/moderator. In such an event remedial action may be taken (in BWRs) by the reactor operator in order to minimize the amount of activity released by the failed fuel rod. No feature of a new nuclear fuel type should impede such remedial action. Conversely, a fuel that limits further activity release after a cladding breach can likely claim a safety benefit for such a feature. In the event that a fuel rod loses integrity and is exposed to the coolant, volatile fission products will escape from the gap/rod plenum, as will some fission products on the surface of the exposed fuel- meat. Different fuel-types have different degrees of leachability of fission products and actinides from the fuel matrix, hence the possibility for different levels of safety credit.

Applying these guidelines

Addressing each of the fuel safety principles can be done on a stand-alone basis or with reference to standard zirconium alloy-clad uranium oxide fuel. Judging fuel safety attributes in this manner yields a ‘safety matrix’ that could facilitate and standardize discussion of the relative merits for various LWR fuel technologies currently under active development.

Eventually, of course, claims must be demonstrated using experimental and modelling means. Nuclear operators and the regulatory community will expect that qualitative safety margin assessments for new fuels are backed up by physical data from instrumented irradiation trials (and post-irradiation examination). At this point there will be a stronger appetite among the fuel development community for quantitative guidance, including values and limits for various fuel properties. This is a laudable goal, but it will take time to attain consensus on what these numbers should be.

Understanding how nuclear fuel evolves with burnup is a complex topic in itself, and so determining safety significance of the various induced changes is not trivial. Fuel properties may provide opposing safety merit in different conditions, for example, in-built cladding porosity may have the disadvantage of allowing fission product gas to pass, yet present the advantage of overall resistance to gross failure in BDBAs. This complexity further supports the finalization of a qualitative fuel assessment framework before a quantified version is attempted.

A ranking or point-scoring system would be inappropriate since it would imply a hierarchy in the importance of fuel safety behaviour in different operating conditions. Debate on this point would be contentious and lessen focus on the enhanced safety features of new fuels.

Linear heat generation limits are a global quantitative indicator of fuel safety margin, though these are established late in the new fuel qualification process. When available, these limits will have value in comparing new fuel types that advance closer to commercialization. Another possible pathway to quantifying fuel safety credentials is by linking their performance to current probabilistic safety cases for the reactors in which the fuels will operate.

Ultimately, in order to be qualified, an advanced fuel needs to be rigorously assessed in terms of its safety-related behaviour in operational, accident and storage conditions. This framework can be a useful early aid in building a comprehensive safety case for a new fuel. However, if there is to be a true driver for the introduction of an advanced fuel, there must be an acceptable trade-off between cost and safety margin.

About this article

Based on the report ‘A Framework for Assessing the Safety of New Nuclear Fuels’ prepared by the World Nuclear Association Fuel Technology Working Group.This article was originally published in the January 2014 issue of Nuclear Engineering International.