Bayardo Materon reviews the progress of construction methods and materials applied in some of the world’s highest concrete face rockfill dams (CFRDs), from the introduction of the compacted fill in the 1970s to present day projects

The evolution of concrete face rockfill dams (CFRDs) during the past 30 years has had an important influence on design and construction methods. Some aspects of design change when the height of the dam increases, while the adoption of new type of contracts, such as build, operate and transfer (BOT) and engineering, procurement and construction (EPC), has motivated designers and contractors to develop innovative construction methods increasing productivity.

This paper comments on the design and construction methods applied in the highest western CFRDs, from the application of vibratory rollers in the 1970s to the actual construction of dams exceeding 200m high. Some Asian and African experiences are also discussed.

A major recognition to the development of CFRDs is given to Chinese Engineering, where dam construction has reached values exceeding the rest of the world.

Chinese evolution in CFRD

According to technical literature the first CFRD designed and built following modern techniques was the 89m high Xibeikou dam, completed in 1985.

The articles ‘High concrete face rock-fill dams in China’ and ‘Development of CFRD in China’ (Jiang Goucheng, Chen Qian et al) give an extensive summary of the experience obtained during the first 15 years of CFRD construction in the country.

Important contributions are the development of articulated plinths on alluvium and the necessity to incorporate vertical and horizontal drains in sand gravel dams, when the permeability is affected by the amount of fines.The rapid increase of CFRDs, totalling a number close to 145, is an important achievement in the development of these structures; this number surpasses the amount of dams of this type in the rest of the world.

High dams progress

Table 1 gives the chronological sequence of some high CFRDs which have contributed to the development of design and construction during the past 30 years.

Most of these dams, where the author has participated in design or construction, will be commented on in the following pages, emphasising aspects of design or construction that were adopted for the first time. These new concepts and experiences have been widely spread and applied in new CFRDs throughout the world.

Design and construction of CFRDs

Cethana dam, Australia

The 110m high Cethana dam was the highest well-compacted CFRD from 1971 to 1974. The design concepts and construction techniques were widely commented (Fitzpatrick et al) during the 1973 ICOLD symposium in Madrid and Rio de Janeiro (Fitzpatrick et al, 1982).

The practical design recommendations opened the door for higher dams developed in the 1970s. Cethana’s performance was excellent, and the sound criteria for compaction and face design are still being applied in dams of similar height.

Alto Anchicaya, Colombia

Alto Anchicaya, 140m high, was the highest CFRD from 1974 to 1980. Its design and performance have been discussed in the 14th ICOLD Symposium (Materón et al) and in the Barry Cooke and James Sherard book, Detroit, 1985. The dam was very well compacted, and the face slab was constructed, for the first time, in two stages using multiple slip forms.

Alto Anchicaya emphasised the importance of providing multiple defenses at the perimetric joint when some leakage was detected. This was well treated by placing mastic over the joint. Since Alto Anchicaya was constructed, many more dams have used mastic as a complementary protection. Aside from the leakage problem, the behaviour of the dam has been satisfactory.

Foz do Areia, Brazil

Foz do Areia, 160m high, was the highest CRFD from 1980 to 1993 and the first CFRD in Brazil. Design of Foz do Areia followed the concepts of Cethana and Alto Anchicaya dams (Pinto, Materón, Marques).

An especial zone under the perimetric joint was used and mastic was designed over this joint. The concept of priority section to optimise the diversion of the river was applied (Pinto, Marques, Maurer). Ramping and construction stages were widely applied for the rockfill and face slab construction was built in two stages.

Productivity in rockfill placement was higher than 500.000m3/month for almost two years (Materón). The performance of Foz do Areia has been excellent after 24 years of operation. After Foz do Areia, 10 CFRDs have been designed, built or are under construction in Brazil.

Salvajina, Colombia

At 148m high, Salvajina dam is one of the highest gravel dams built in a seismic area (Sierra, Hacelas et al). The concept of plinth design was adjusted to the geology, which varied from saprolite to fresh sandstone. Plinth gradients were defined for the different types of foundation. The perimetric joint was designed with copper water stop and mastic. Face slab was constructed in three stages and double parapet was designed for reducing dam volume. The upstream slope was treated with shotcrete and some minor cracking and spalling was observed. Copper waterstop was placed directly at the dam site, reducing welding. Salvajina dam showed that dense quaternary deposits may remain in the dam and that compacted gravel is remarkably less compressible than the compacted rockfill (Hacelas, Ramirez). Leakage was nominal, and the performance of the dam has been satisfactory (Amaya, Marulanda).

Aguamilpa, Mexico

At 187m high, Aguamilpa is the highest CFRD in operation in the world. The dam was built with gravel and rockfill. As observed in Salvajina, the compressibility of the rockfill proved to be much higher than the compacted gravel fill. Aguamilpa was designed following the concept of a priority section and the possibility of cofferdam overtopping during construction. The main cofferdam was overtopped twice due to ‘El Niño’ phenomena, but the priority section protected the dam. A fuse in the main cofferdam also protected the structure. The face slab was built in three stages (Castro).

Horizontal cracks have been observed at the upper face slab due to high tensile stress produced by the compressible rockfill adjacent to high modulus gravel (Macedo). Aside from the problem of horizontal cracks the performance of the dam is satisfactory.

Santa Juana and Puclaro, Chile

Santa Juana, 113m high, and Puclaro, 83m high, are gravel dams built over alluvium deposits with articulated plinth and concrete diaphragm (Anguita, Alvarez , Vidal).

The concept of articulated plinth followed the Chinese experience in similar dams. Performance has been excellent. In October 1997 a seismic event with M=6.8 shook the Santa Juana dam producing settlement of 9.7cm within the design tolerances (Noguera, Pinilla, San Martin). Since these Chilean dams have been built, similar solutions have been adopted for CFRDs on alluviums in Argentina and Peru.

Xingo, Brazil

The 150m high Xingo dam is the second highest dam in operation in Brazil. Design (Vasconselos, Eigenheer), construction (Materon, Pitanga, Arfelli) and performance (Eigenheer, Silva, Casarin, Barbosa) has been discussed in technical literature. The face slab was built in two stages, with gaps between the first stage of face slab and the rockfill duly grouted. Xingo used a transition material zone 2, with very high amount of fines (10-12%). Cracks in zone 2 during construction and in the face slab during operation were noted, which was probably due to differential settlements.

The case of Xingo emphasised the importance of analysing the topographic profile of the valley, which may produce differential settlements after filling of the reservoir. It was also observed that compacted fills under creep deformation increase movement notably when saturation due to slab cracks is produced. The performance of the dam after reducing leakage with fines is satisfactory.

Tian Shen Qiao, China

Tian Shen Qiao I, 178m high, is the highest CFRD in operation in Asia and the second highest in the world. The design of TSQ I has been presented in many articles (Cao Keming et al), in international magazines and in the Chinese symposiums of 1993(Yang) and 2000(Wu, Freitas, Araya). Handling of the river by overtopping the fill and rising of the fill in stages was well managed during construction. For the first time in CFRDs, the rock-fill placement exceeded 1Mm3/month, demonstrating the construction advantages of this type of dam.

As in Aguamilpa, the face slab was built in three stages observing the presence of gaps between the face slab and the fill. Horizontal cracks were detected in the zone 2 and face slab, which were well treated.

Tensile strains due to rockfill creep were causing these cracks. The performance of the dam is satisfactory and the leakage nominal for the height and face slab area.

Itá and Itapebi, Brazil

Itá, standing 125m high and Itapebi, 120m high, are rockfill dams built with compacted basalt and gneiss respectively.

Performance and design of Itá dam has been discussed by Antunes, Resende et al.

The priority section was built downstream and different material quality was used in the traditional 3B zone.

The extruded curb (Resende, Materón) was developed for the first time in Itá and the benefits of this construction method has been applied in new CFRDs. Itá dam presented high leakage (1470l/sec) during first filling which increased due to saturation of the fill. Creep movements increased when the fill was subject to saturation after construction. Similar rockfill behaviour was observed at Xingó dam in Brazil.

Treatment by throwing fine material into the reservoir was very effective. Actual leakage is less than 140l/sec.

Itapebi dam was built on sand deposits as shown in Figure 1. Innovative construction methods have been discussed by Materón and Resende and the dam performance by Resende et al. Plinth was built by slip-forming using the internal slab technique for reducing excavation.

Itapebi was the first dam where construction of the face slab was simultaneously done with upstream rockfill placement. The upstream slope was 1.25H: 1V. A coordinated operation was carried out to build the slab and the upstream fill. Details are shown in Figures 2, 3 and 4. Photos 1 and 2 illustrate the final result. Leakage was relatively high and augmented by cracking of the slab due to further saturation of the fill increasing creep and tensile strains at the face slab.

As in Itá, throwing fines into the reservoir effectively treated the leakage. Reduction of leakage from 1700l/sec to 50l/sec has been obtained. Both dams are operating satisfactorily.

Antamina, Peru

The 109m high Antamina dam is a CFRD built for retaining tailing deposits. Its final height will be 210m when exploitation of the copper mine is complete. Description of the dam and main aspects of design are giving in the Chinese 2000 symposium about CFRDs (Marulanda, Amaya).

Antamina starter dam was built using the techniques of a high-extruded curb construction to accelerate the production of the fill.

Since the starter dam is required for the first few months of the mine exploitation, the face slab was built only for this stage, and was of constant thickness. For higher levels a wide zone of 2B material was provided.

The Antamina dam was built quickly with the waste rock of the mine by hauling units of 240t capacity. Leakage is nominal.

Machadinho, Brazil

Machadinho, 125m high, is located in the south of Brazil (Mauro, Humes, Alves). Due to the presence of basaltic acid flows the plinth was located in very high walls keeping the geometry of the original design. These walls vary in height reaching values up to 20m high. Stability was granted by tendons and drainage reducing uplift pressures. The design of these walls was a compromise to ensure the construction schedule was met. Machadinho used the extruded curb and for the first time developed a pre-cast parapet design for completion of the dam.

Mohale, Lesotho

Mohale, 145m high, is the highest CFRD in Africa built in basalt. It was designed following the use of priority section optimising the diversion tunnel. The face slab was built in two stages using the extruding technique for placing zone 2. As observed in other dams, some gaps developed between the extruded curb and fill which were extensively grouted. Plinth was grouted using the GIN method. Although the performance is adequate the dam is still in the process of reservoir filling.

Barra Grande and Campos Novos, Brazil

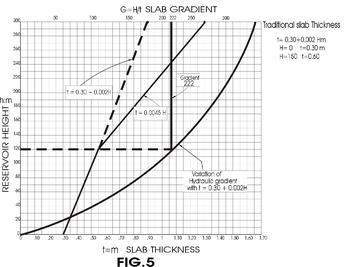

The 185m high Barra Grande and 202m high Campos Novos CFRDs are under construction in Brazil. Design concepts are presented by Albertoni et al., and construction aspects were discussed in the September and October 2003 issues of International Water Power & Dam Construction (Materón et al). The observation of cracks in high dams have motivated designers to better specify compaction and face slab dimensions thicker than the traditional formula of:

T=0.30 + 0.002H m.

When the high of the dam exceeds 120m (Pinto, Materón) the slab is designed with a new formula equal to:

T=0,0045H m.

Keeping the slab gradient relatively constant, equal to 222 (Figure 5). The concept of internal and external slab used in Itá and Itapebi was also defined for these dams.

The importance of building the plinth simultaneously with the diversion tunnels was again demonstrated during the construction. Barra Grande reached production peaks higher than 1,000.000m3/month, and Campos Novos was always ahead of the contractual schedule. Extruded curb, 0.5m high, and vibratory compactors of 12t were essential for reaching high productions. The use of precast parapets, as constructed in Machadinho dam for the first time in Brazil, was selected for both dams.

Bakun, Malaysia

The 205m high Bakun dam is under construction in Borneo, Malaysia. It will be Asia’s second highest when completed and one of the highest CFRDs in the world. Bakun is being designed with all the modern concepts for external and internal plinth, extruded curb, face slab, parapet and very well compacted fill. The dam will be built with Greywacke and adequate mixtures of Greywacke and shales. The priority section for protecting the dam against 1:500 year floods is under construction.

El Cajón, Mexico

The El Cajon dam, 187m high, is currently under construction. It is located upstream of Aguamilpa dam and will be built using very well compacted Ignibrite rock. The dam follows the principles of CFRD design. The owner, Comisión Federal de Electricidad, is studying and developing two more CFRDs – La Parota, 165m high and La Yesca 205m high – in the near future.

Kárahjúkar, Iceland

The 196m high Kárahjúkar dam is under construction in Iceland. It will be Europe’s highest CFRD when completed. Information about design aspects was given in Hydro Power & dams 2001 (Johannesson). The dam is very well compacted in layers, varying between 0.40m (Zone 2) and 0.80m, by a vibratory roller, 12t capacity. The unique canyon of the river, 45m deep, required a solution with a concrete dam, where the plinth is located.

The dam will be built mostly with recent basalt and pillow lava, transported by conveyors to the dam after crushing the material to smaller sizes. The Kárahnjúkar dam has adopted all the new concepts of design for the plinth, face slab and reinforcement of critical zones. (See pp32-35 for more information Kárahnjúkar).

Shuibuya, China

Shuibuya, at 233m high, will be the highest CFRD in the world when completed. It currently stands at 170m high, with the first stage of the face slab having been completed. Fill control is being applied using modern techniques based in GPS control.

Conclusions

The practical construction and remarkable behaviour of CFRDs, during the past 30 years, has contributed to the notable development of these structures. The increase in height has progressed from 110m, Cethana Australia, 1971 to 233m, Shuibuya, China 2005.

Recent observations in high dams have indicated the importance of:

• Providing multiple defenses at the perimetric joint.

• Compacting better downstream zones, using heavier vibratory rollers (12t).

• Designing plinths according to geology with practical gradients.

• Increasing reinforcement close to abutments and areas of high potential tensile strains.

• Using thicker face slab thickness than those provided by the traditional lineal formula, when the dam pass 120m in height.

Construction productivity has increased due to:

• The priority given to early plinth construction.

• The development of the extruded curb, for stabilising the upstream slope.

• Using upstream priority sections of rockfill to optimise diversion.

• Using innovative construction methods such as intermediate platforms for building face slab simultaneously with upstream rockfill.

• Liberal use of ramps in the fill construction.

• Adopting pre-cast parapet walls for the dam crest.

• Adopting conveyor systems for rockfill distribution.

• Simpler slip-forming for face slab and plinth construction.

• New water stop systems and in field methods of installations.

Performance of the CFRDs has proven to be:

• A rapid solution for hydro and irrigation projects.

• Adequate for retaining tailing deposits.

• Adequate and inherently safe for seismic areas.

• Stable under leakage when proper zoning is provided.

In summary, CFRD’s design has proven to be a technical, practical and economical solution for multiple purposes.

Author Info:

Bayardo Materón, Consulting Engineer, Bayardo Materón & Associates, Av. Giovanni Gronchi 5445, Sala 172, 05724-003 São Paulo- Brazil, bmateron@ajato.com.br, BAYARDOMATERON@aol.com

The author acknowledges contribution provided by the field staff and authors associated to the referred dams in the paper. A special recognition and tribute is given to J. Barry Cooke, prominent engineer, who during these 30 years participated in the projects and dedicated unceasing efforts to improve the design and progress of concrete face rockfill dams. Barry passed away on 21 April this year.

TablesTable 1