Focus on five decommissioning projects that are currently underway at Kozloduy 1-4 in Bulgaria.

Project 9b: evaporator waste project

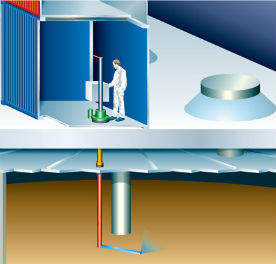

One significant project that is currently underway (Project 9b) is the implementation of a facility for retrieval and processing of the solidified waste from evaporator concentrate tanks.

Ten tanks, each with a capacity of 500m3, store concentrates resulting from the evaporation of contaminated water treatment systems. Five tanks are located in Auxiliary Building 1, with five more in Building 2.

In February 2009, Onet Technologies of France won a contract from the Kozloduy International Decommissioning Support Fund, administered by the European Bank for Reconstruction and Development, for design, equipment manufacturing, construction and commissioning of a facility for retrieval and processing of the solidified phase from the evaporator concentrate tanks.

The project aims to separate the concentrates into clean boric crystals and category 1 waste (which can be considered as conventional waste after five years of decay.

The project includes the use of two mobile systems: the first for extraction of the solidified phase, and a second installation for processing of the waste.

Retrieval and characterization of samples from the evaporator concentration tanks have been completed, along with factory tests for the separation of borates from the solid phase. The project is expected to be completed in February 2015.

Project 5a: Retrieval of ion exchange resins

Project 5a involves the design and manufacture of equipment for sampling and retrieval of ion exchange (IX) resins from storage tanks. The resins were used to treat contaminated water during power plant operation. They are currently stored in six tanks: one intermediate-level-waste tank and two low-level-waste tanks in each of the auxiliary buildings. A manhole above each tank is the only means of access.

A consortium of ENSA & Gas Natural Fenosa Engineering has been awarded a contract for retrieval and conditioning of the IX resins. The project includes development of a methodology for sampling and characterization, along with a sampling plan. SERAW personnel will be responsible for carrying out the sampling and analysis.

The contract also includes a preliminary assessment of the available radiochemical laboratories to characterize samples. A list of any additional equipment needed will be prepared. Delivery of this equipment is part of another project – 5d.

The engineers’ estimate for contract completion is February 2018.

Project 12a: Size reduction and decontamination workshop

Project 12a is for design, construction, supply, installation and testing of a workshop (including equipment) for size reduction and decontamination of materials arising from the dismantling of KNPP 1-4.

The main contractor for this project is a consortium of ONET Technologies and RISK Engineering.

The workshop is expected to enter operation by mid-2016. It will be used for size-reduction of material by cutting, decontamination using mechanical, chemical and electrochemical methods, as well as packaging of the treated materials in pallets and placement in 20-foot ISO containers for transport to the Free Release Measurement Facility.

Project 19-4: Temporary storage sites

Project 19-4 is for the design, construction, licensing and commissioning of four sites intended as temporary storage facilities for 20-foot ISO containers, and one site for temporary storage of skips containing non-radioactive materials (scrap). These facilities will store waste up to 2030.

The project is a priority for the implementation of decommissioning activities, and is due to be completed by August 2015.

About the author

Denitsa Dishkova, International Project Management Division, State Enterprise "Radioactive Waste", Bulgaria. For a more general overview of decommissioning work at Kozloduy see Clearing out Kozloduy 1-4