Ansaldo Caldaie is supplying HRSGs of the once through Siemens Benson type to the new generation of combined cycle plants under construction in Germany. The Ansaldo technology is the result of an intensive development effort to tailor its horizontal HRSGs to the requirements of the Benson once through concept.

To meet the power market’s increasing demand for greater cycling capabilities and fast start-up and to be ready for the next generation of high efficiency combined cycles, based on high pressure and temperature steam requirements, Ansaldo Caldaie acquired Benson once through HRSG technology from Siemens, in 2003 (the company has been a Siemens Benson licensee for utility boilers since 1995).

At the beginning of 2005, Ansaldo Caldaie signed a Multiple Purchase Agreement with Siemens to supply HRSGs based on HP evaporator Benson technology or, as an option, with natural circulation. Then, in the middle of 2005 Ansaldo won two Benson HRSG contracts from Siemens for units downstream of V94.3A(4) gas turbines. The two projects are in Germany:

• Mark E’s 400 MW Herdecke combined cycle plant – multiple shaft configuration, triple level HRSG with reheater, Benson high pressure system; and

• Trianel Energie’s 800 MW Hamm Uentrop combined cycle plant – two single shaft triple level with reheater HRSGs with Benson high pressure system.

Both plants are scheduled to enter operation in summer 2007.

Development programme

The once through Benson technology to be used in these plants (Figure 1) has been successfully proven at the Cottam power plant in England (with triple-pressure HRSG downstream of a Siemens V94.3A gas turbine), as described in Modern Power Systems, September 1999, pp 40-43 and July 2000, pp 33-35.

Following acquisition of the Benson once through technology in 2003 Ansaldo undertook an intensive development programme on adapting its horizontal HRSGs to meet the functional requirements of the Benson technology. This effort resulted in the Multiple Purchase Agreement with Siemens, under which the two companies intend to co-operate closely over the next three years on the development, tendering, standardisation and total cost reduction in the provision of both Benson type and drum type HRSGs for V94.3A(4) gas turbines.

The HRSGs being developed under the MPA are triple pressure with reheater, HP Benson type (drum type as an option). They have the following main steam parameters:

Flow Pressure Temperature

(kg/s) (bar) (°C)

HP steam 77.3 129.9 566.5

RH steam 91.1 30.7 565.1

LP steam 10.6 4.4 234.6

The standard designs for both the drum and Benson type HRSGs have been completed. To minimise differences between the two, the development work has focused on applying modifications to the HP evaporator module only. The main differences are:

• Drum in natural circulation HRSG and separator in Benson type.

• Dissimilar HP evaporator internal and external piping.

• Additional superheater in the drum type HRSG since the Benson design steam temperature at the evaporator outlet is 75°C superheated.

Figure 2 shows the HP evaporator flow diagram and the HP evaporator arrangement developed for the MPA standard design.

The HP evaporator consists of two sections (EVA1 and EVA2) connected in series on the exhaust gas side. In each stage there is an upward cross-flow arrangement. Wet steam leaving EVA1 is collected through risers and downcomers and flows to the star distributors placed on the bottom of the evaporator. It is then distributed into the second evaporator stage EVA2. Flow at the EVA2 outlet is about 75°C superheated, as already noted, to allow sufficient range for main steam temperature control by feedwater mass flow alone during part load operation and at varying ambient conditions.

A piping system takes steam from the separator to the high pressure superheater. During start-up and at very low load the flow at the EVA2 outlet is wet steam and the separator removes steam from the water. The water can be recirculated from the water collecting vessel to EVA1 through the start-up recirculation line.

Fugure 3 shows an isometric view of the Benson type evaporator.

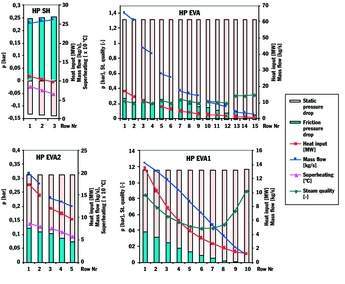

Figures 4 and 5 show, respectively, main thermal performance data for a drum type and a Benson type HP evaporator.

The EVA1 static head and friction loss bar chart shows how hydrostatic pressure drop decreases in the hottest tubes due to the increased steam fraction. In order to maintain the same overall pressure drop in all parallel circuits, steam water mixture flow increases in these tubes until frictional loss and static head sum is equal in all circuits. This is the basis of the Siemens Benson technology. Higher mass flow is achieved in the hotter tubes and lower mass flow in the colder ones. This means that steam quality at the tube outlet is uniform in all the parallel tubes. No individual orifice in the single tubes or tube rows is necessary.

Figure 6 shows high pressure evaporator pinch diagrams for both configurations.

Cycling behaviour comparison

The most interesting feature of Benson once-through technology is the possibility of operating the HRSG with steep start-up and shutdown gradients, which means fast start-up and short load variation time. This is due to the absence of the high pressure drum, which greatly limits allowable temperature gradients due to its large wall thickness. The stresses induced by temperature gradients during start-up and shut-down cycles are a major factor in thick component fatigue life consumption.

To optimise start-up time in terms of overall plant life consumption, we carried out a fatigue analysis on the various HRSG types. To simplify the comparison only start-up and shutdown cycles were taken into consideration, without taking into account load variations and abnormal cases such as gas turbine trip.

The fatigue analysis and start-up optimisation was done for three cases:

• drum type, normal, with typical start-up for such an HRSG;

• drum type, fast, with optimisation of the temperature gradient to control fatigue life consumption;

• Benson type.

Figure 7 shows the number of cycles considered while Figure 8 shows the fatigue life consumption due to these cycles. Comparison of the figures shows how Benson type HRSG life consumption has been reduced by more than 60% compared with the drum type HRSG allowing a higher number of cycles.

Start-up curves for the various cases are presented in Figure 9 (time for steam turbine warming has not been taken into consideration). It can be seen how the total start-up time has been reduced by about 20% for the drum type fast case, and by about 60% in the Benson case.

Weight comparison

Figure 10 shows the weight of the drum type HP evaporator compared with the Benson type. The Benson achieves a weight reduction of about 5%. But it should also be noted that the Benson technology has not yet been optimised to the extent that the well known and long established drum type HRSG has been.

The Benson type HP evaporator system does not have the weight of the drum but there is a greater weight of evaporator connecting pipework due to the more complex internal piping.

The Benson evaporator also has a higher fin weight, due to specific characteristics of the Ansaldo Caldaie Benson evaporator design.

Promising characteristics

Overall, our experience gained during development of the new German plants confirms the promising characteristics of the Benson design in terms of optimum cycling performance and weight reduction.