More and more, components’ health and performance can be monitored during operation. Making use of the large amounts of data generated by such sensors requires not only sophisticated computing but also a great deal of industry experience. A new EPRI pilot programme aims to bring both together. By Richard Rusaw

Diagnosing potential problems at nuclear plants can take significant time and plant resources. While huge amounts of data are now available through on-line monitoring systems and other condition assessment devices, separating the wheat from the chaff to find an imminent or emerging problem is no simple task.

EPRI is developing a prognostics and health management software tool that nuclear plants could use to support such efforts. For example, an unusually high temperature reading for a pump or motor bearing can be the first sign of equipment problems, but if it is corrected promptly extensive damage can be avoided. The software automatically recognizes the high temperature reading and alerts the user, setting out the possible problems causing that condition. The software then obtains other information from the user to determine which of several possible problems needs to be corrected.

Fleet-Wide Prognostics and Health Management tool

The software tool, called Fleet-Wide Prognostics and Health Management (FW-PHM), enhances monitoring by integrating a number of technologies, including on-line advanced pattern recognition, automated diagnostics, and remaining useful life (RUL) algorithms. The tool was pilot-tested at several nuclear plants in 2013, and demonstrated that it could reduce the time it takes to diagnose problems and allow system engineers to focus their efforts on solving them. The full software package will be available for broader use by the middle of this year.

Monitoring technology like the system used by FW-PHM is at the leading edge of advanced industrial management information systems. Grounded in so-called ‘big data’ analytics, industrial monitoring technology automatically provides information that plant personnel can use to improve plant reliability, efficiency and productivity.

Industrial and economic productivity advances over the last three decades have been based on developing and applying digital information and control technologies. The nuclear power industry has been slow to adopt these technologies as its plants have aged. Its current business model and hardware is based in the 1980s and may struggle to keep up with competitors if the industry does not adopt a high-productivity business model. Monitoring technologies have already established their cost-effectiveness. Waiting to adopt them could increase the cost of operations and limit the long-term economic viability of nuclear plants.

The FW-PHM Suite software allows nuclear plant personnel to make better-informed decisions about operations and maintenance. It can:

- Mitigate equipment failures. The plant staff can anticipate and avoid equipment issues that could limit plant production or reduce asset life.

- Improve reliability and productivity. The tool helps develop troubleshooting plans for the plant that can be used until the fault can be remedied. As it helps guide the troubleshooting process, the tool continues to ask questions as new information is presented, helping the plant engineer decide what is the next-most important piece of information to gather.

- Create a more formal record of the diagnostic experience on an industry wide scale. When a systematic cause is determined, plants can change their response so that the problem does not recur.

- Expand knowledge. The system "learns" every time it is used, through continuous database development. Although each plant or utility has its own monitoring centre, EPRI will collect new troubleshooting information from plant experience, compile it, and provide it back to all users.

- Boost plant health. By capturing the knowledge of experienced engineers – many of whom have been running their plants safely and reliably for decades and may be leaving the workforce – the tool helps provide continuous asset health management independent of, yet integrated with, the knowledge base of the plant staff.

Limitations of existing technology

There are many industry examples where significant savings have arisen because monitoring programmes that provide timely corrective or preventive maintenance have avoided a loss of production or a catastrophic failure. For power plant applications, however, the engineering effort to evaluate anomalies and to provide a useful diagnosis of real degradations has been a barrier to wide application of the technology. EPRI recognised the need for an automated diagnostic and prognostic advisor to screen anomalies and provide diagnostic information instantaneously before engineering is engaged in the process.

Moreover, most nuclear plants do not have an automated learning structure in place for capturing the experience gained while troubleshooting and then solving problems. As a result, some industry-wide issues go through the same lengthy diagnostic process again and again.

Providing a risk-informed remaining useful life estimate would enable a plant to prioritise maintenance activities. If properly automated, this capability would fill the gap between the need for timely, accurate performance analysis and the availability of plant engineering resources. The engineering focus could be shifted from identifying potential problems, diagnosing asset failures, and providing maintenance guidance to actually solving the problem. Valuable operating assets could avoid premature or untimely failure, or avoid life-limiting modes of operation.

How the software works

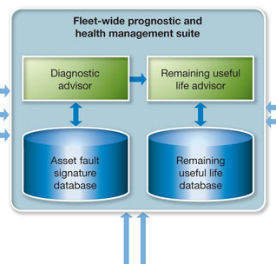

The FW-PHM software suite is built on four core modules:

- Diagnostic Advisor identifies impending failures by comparing asset fault signatures with operating data

- Asset Fault Signature (AFS) database organises asset fault signatures collected from across the industry for each asset type

- Remaining Life Advisor provides risk-informed estimates of how long an ageing or faulty asset will continue to provide reliable service

- Remaining Useful Life (RUL) database organises asset remaining-life signatures collected from across the industry.

The software integrates diverse information from online monitoring, trending, and other plant process data, including advanced pattern recognition (APR). This technology was developed by the US Department of Energy and NASA in the 1990s. Commercial APR products are available and are in wide use in aviation, electric power, information technology and other industries. The technology makes use of continuous monitoring of component and plant parameters that are sensitive to equipment performance.

The APR system learns patterns of behaviour that represent healthy states of systems or equipment. When these patterns diverge from normal patterns, the system reports the anomaly as an indicator of potential degradation. These anomalies must be analysed to diagnose specific problems.

EPRI’s FW-PHM tool incorporates a Diagnostic Advisor, which uses anomaly triggers to automatically match monitored equipment conditions to a database of fault signatures representing equipment-specific failure modes. The Diagnostic Advisor provides a ranked order of possible failure modes that match current conditions, while suggesting additional information that would improve the diagnosis.

EPRI will maintain two database modules that provide a common format for collecting and indexing industry data so that the fault signatures and remaining-life models can be used across the power industry. This is critical because it is unlikely that a single unit, plant, or utility will experience most of the faults and ageing scenarios possible during an asset’s lifetime. Users will have real-time access to broad industry experience of asset health management without having to expend their own resources.

The FW-PHM Signature Database is used to catalogue asset fault signatures and remaining useful life signatures. The Signature Database includes two schemas installed at a subscriber (end user) site. One schema contains master tables that hold master records created by EPRI. The other schema contains subscriber tables that hold records created by the subscriber (see Figure 2). This structure enables EPRI to provide periodic updates of the master database to subscribing end users.

The FW-PHM software suite is a web-based, enterprise-scale tool designed specifically for compatibility and integration with power utility information technology and business processes. The software is designed to adapt easily to asset-naming conventions, information sources, and management processes that will likely differ by plant, but which can be aggregated into a comprehensive, fleet-wide view for authorised users.

The software also is designed to be a learning application that improves over time as new asset fault conditions and operating life information are discovered and catalogued by users. The database modules organise the new information and allow it to be retrieved and used.

Industry pilots and technology transfer

The FW-PHM suite is in the final stages of beta installation and testing. The beta testing phase has been a cooperation between the US Department of Energy’s Light Water Reactor Sustainability Program (LWRS) and several industry pilot applications. Installation, set-up, and operation is under way at the DOE’s Idaho National Laboratory (INL), Exelon, Duke Energy, EDF Research and Luminant.

Three host plants are testing the functionality of the software tool, focusing on separate component applications: an emergency diesel generator at Exelon’s Braidwood nuclear station; generator step-up transformers at Duke Energy’s Shearon Harris nuclear station; and a horizontal pump at Luminant’s Comanche Peak nuclear station. These pilot projects were selected because the utilities involved had a well-developed APR monitoring infrastructure, the plants had an asset with considerable monitoring capability already developed, and both plant management and the utility could devote resources to the programme.

The emergency diesel generators at Braidwood are equipped with digital data logging platforms and monitored with APR models. Engineers at Braidwood are working with Exelon’s nuclear monitoring programme manager, EPRI and INL to adapt the FW-PHM application to generators. Fault signatures have been developed for many of the common system failure modes.

The generator step-up transformers at Shearon Harris are equipped with fully-featured digital monitoring platforms that provide real-time operating data. Duke’s SmartGen M&D monitoring centre has developed APR models to monitor the transformers and is working with EPRI on the FW-PHM application for transformer fault signatures.

EPRI and reliability engineering staff at the Comanche Peak Nuclear Station have installed the FW-PHM suite and are developing a pilot application for the heater drain pump and motor combination. Component experts will work with EPRI to develop the fault signatures for inclusion in the database. There are plans to install the software suite at the Luminant Performance Optimization Centre and continue application and development of fault signatures for high-value assets.

Scientists at INL and the LWRS programme have been working with EPRI to conduct formal beta testing, develop fault signatures in support of the pilot applications, test the Diagnostic Advisor, and develop RUL models. The Diagnostic Advisor was formally demonstrated at Idaho National Laboratory in the fall of 2013. Known failure modes were embedded into operating data from the pilot plants and tested for effectiveness. To assist in describing the scope and capabilities of FW-PHM, EPRI and INL developed a short video, available via http://tinyurl.com/eprifwphm.

For 2014, EPRI is focused on final software development and technology transfer. The production version of the FW-PHM software is scheduled for release to commercial interests in mid-2014. The fault signature database will be developed and populated in 2014, focusing on assets with broad power industry application, including station transformers, emergency diesel generators, main generator, horizontal and vertical pumps and motors, turbine feed water pumps, valves and gas turbines. These signatures will form the foundation for the production release of the master fault signature database at the end of 2014.

In 2015 EPRI will focus on technology transfer and support for users. EPRI will also focus on developing and managing the fault signature database, researching the RUL capability, and extending the application to passive assets in support of plant operation beyond 60 years.

INL will continue to develop generator step-up transformer fault signatures and test them against the Diagnostic Advisor. New research will develop remaining useful life models for common step-up transformer failure modes, followed by a demonstration of the RUL Advisor, utilising embedded failure modes in normal transformer operating data.

About the author

Richard Rusaw, rrusaw@epri.com, senior project manager, Electric Power Research Institute, 1300 West W.T. Harris Boulevard, Charlotte, NC 28262, USA