Gas turbines are increasingly being required to cope with wide and rapid variations in fuel properties. A combustion operating concept has been developed for the Alstom GT24/GT26 machines that can handle gases with large proportions of the higher hydrocarbons as well as a large percentage of inerts (eg CO2 and N2). Using an infrared sensor it can also respond very quickly to changes in gas composition.

The range of natural gases being combusted in gas turbines is growing, notably in Brazil, Algeria and parts of Asia, with ever widening variations in terms of species composition, Wobbe Index and heating value (LHV), see Figure 1.

The gas composition may include large proportions of rich gases or “C2+” (ie higher hydrocarbons with two or more C atoms). At the same time the inert content of natural gases, mainly CO2 and N2, may be large. In Thailand, for example, a typical natural gas composition might be 16% C2+ with 19% inerts.

In a given gas pipeline, the variations in C2+ and inerts are also turning out to be wider than originally anticipated and to fluctuate much faster than expected. For example recent measurements show that C2+ content can go from 9 to 15% within as little as 30 seconds. Such step changes can for example be triggered by the trip of a gas separation plant 90 km and 45 minutes upstream of the gas turbine and are typical for large pipeline networks.

To deal with these conditions, Alstom has developed a combustion operating concept that can handle high hydrocarbon gases and high inert contents in the two stage combustors of the GT24/GT26. In particular it can handle high speeds of change in gas composition.

The operating concept has been developed within Alstom’s fuel flexibility development programme, which included various rig scale combustion tests and engine scale tests on the company’s in-house GT26 validation unit.

The various C2+ and inert contents have been simulated with gas mixtures made up of natural gas from the local gas supply and from ethane, propane, butane, CO2 and N2. A key element of the programme was the full engine test on the GT26 validation engine in Birr, Switzerland. In this test campaign propane and N2 were mixed with the Swiss natural gas on-line.

The combustion characteristics were evaluated with high resolution monitoring and measuring systems for gas composition, flame position, combustor hardware temperatures and pulsations in both annular combustors. The results in summary are as follows:

• The primary combustor stage, which has EV burners, is insensitive to changes in C2+ content. With increasing C2+ content the EV flame does not retract into the EV burner. There is no risk for EV hardware in the C2+ range tested, up to more than 30% (by vol).

• The combustor operating window of the EV combustor increases with increasing C2+ content. The EV lean extinction pulsations disappear with increasing C2+ content and the operating window becomes larger at the lower temperature end with the lean extinction limit diminishing.

• The inert content can be handled with a slight modification to the EV burner premix fuel

injection. The modified EV burner works for low and high C2+ gases at the same time with slightly lower NOx emissions than the original design.

• In the case of the secondary, SEV, combustors, operation requires the adjustment of the SEV burner inlet temperature depending on the C2+ content as the only modification. All other parameters, in particular the SEV flame temperature have no or negligible influence on the flame position with high C2+. There is no risk to the SEV hardware in the C2+ range tested (>30%), irrespective of inert content.

• The SEV burner is insensitive to the changes in the inert content of the natural gas in the range tested up to 30% and LHV down to 32 MJ/kg.

• The NOx emissions with high C2+ content are well within the emission limits.

• The CO emissions decrease with increasing C2+ content and remain well within the guaranteed limits.

The resulting operating and protection concept for high C2+ fuel gases is summarised in Figure 2. It illustrates the operating window (green) in terms of SEV burner inlet temperature versus C2+ content. The operating range for high C2+ fuel gases is limited at the top through the SEV metal temperatures and at the bottom through the lean extinction limit of the EV combustor. It is valid independent of the inert content.

Fast on-line gas sensor

An infrared (IR) based fast on-line gas sensor has been crucial to implementation of the new operating concept in the GT24 and GT26 fleet. Figure 3 compares readings from the IR system with those from a conventional gas chromatograph (GC), which is a standard measuring device in gas supply networks and in most natural gas power plants. As Figure 3 shows the GC cannot follow the change. Only after a lag time of about half an hour does the gas chromatograph report the full variation in C2+.

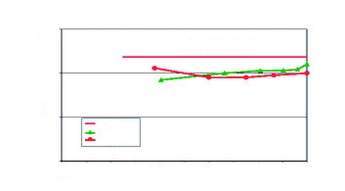

The IR sensor has been developed for speed, accuracy for the various gas composition ranges and reliability under field conditions. It has a response time of less than 1 second, with much longer maintenance and calibration intervals than for a gas chromatograph.In GT24 and GT26 field engines working with high C2+ fuel gas the control and protection system has been connected to the IR sensor signal and the SEV burner inlet temperature then follows the C2+ content closely. Field experience has been flawless. Figure 4 shows typical results.

Field experience

The field experience to date with Alstom’s dual stage combustors covers currently nineteen GT24 and GT26 field engines operating on high C2+ fuel gas supplies. They have logged 290 000 OH, 167 000 of which have been obtained with high C2+ content fuel, between 9% and 16%. Inert contents in the field have been as high as 20%.

The availability has been excellent over the extended fuel gas composition ranges and emission performance has been excellent as well, with NOx emissions well within the guaranteed limits (Figure 5), and several cases in the single digit range. CO emissions with high C2+ gas are lower than for low C2+ fuel gas and within guaranteed limits as well.

The field engines for high C2+ and high inert gas include four instrumented units with measuring and monitoring equipment at the SEV burners similar to the GT26B validation engine in Switzerland. That instrumentation allows verification of the operating and protection concept in the field. That covers different operating conditions and a longer period in terms of operating hours and engine starts. The operating conditions include variation of the natural gas composition, in terms of C2+ and inert content, ambient temperature and humidity and transient conditions.

There are two key inputs for the operating concept at the SEV combustor: the combustor metal temperatures; and the relationship between combustor metal temperatures and the engine operating parameters.

The lifetime assessment delivers maximum sustainable hardware temperatures in the hot gas path. The relationship between SEV metal temperatures and engine control parameters, namely the SEV burner inlet temperature, has been recorded in instrumented GT24 and GT26 field engines. These data have been used for in-field validation of the operating concept.

Figure 6 shows the typical readings of hardware temperature versus burner inlet temperature in the 24 SEV burners of one instrumented GT26 engine. The C2+ content remains constant. The data scatter extends over 100K in SEV burner metal temperature and about 160K in burner inlet temperature. That requires a statistical approach. It turns out that in spite of the scatter the data quality is high and leads to a consistent result. The data exhibit a strongly Gaussian distribution with a small standard deviation.

The probability of one burner of the complete assembly exceeding the maximum permissible hardware temperature can be derived and the results confirm the soundness of the original protection concept.

Kinetic modelling

Kinetic modelling has also confirmed the validity of the approach for high C2+ fuel gases.

Recently shock tube experiments have validated the kinetic modelling that was applied to define model gases for the rig and engine scale tests with gas mixtures. The model gases were defined by matching mainly the auto-ignition delay time, but also the Wobbe Index, density and heating value to the actual gases being used in the field.

In the case of the GT26 validation tests in Birr the gas mixtures contained Swiss natural gas, propane and N2 and had to match, for example, Thai natural gas, with auto-ignition delay time being calculated using simulations of the chemical reaction mechanism. The shock tube experiments have allowed these results to be validated and show, for example, that the GRI3.0 kinetic model gives less good predictions for the gas mixtures than other models. GRI3.0 predicts a difference in speed between ethane and propane, which is not found in the experiments. Another kinetic model is found to perform better in this regard. Figure 7 shows the different kinetic models for various ratios of ethane and propane at constant C2+content. The reaction mechanism B reflects the shock tube results more precisely, which indicate no difference between ethane and propane.

The results support the basing of the gas turbine control and protection concept for the GT24/GT26 SEV combustors on C2+ alone, while neglecting the differences of the individual higher hydrocarbons. That holds irrespective of the inert content. The characteristic of the relationship between C2+ content and auto-ignition delay time remains unchanged and is illustrated in Figure 8.

The validation results from the GT26 test engine in Switzerland cover a range of natural gases as shown in Figure 8. That together with field experience forms the basis for the possible extension of the operation window towards higher C2+ levels.

Figure 1. Plot of LHV vs C2+ content for various natural gases in today’s markets, as encountered at GT26 sites. The red symbols indicate fuels with high inert content Figure 2. The operating concept of the GT24 and GT26 engines for low and high C2+ gases in the range up to 16%. The operating window lies between the maximum SEV burner metal temperature and the lean extinction limit of the EV combustor. The concept has bFigure 3. Rapid change in the C2+ content in a large gas pipeline network from 9% to 15% within 30 sec. The measurements are recorded from two independent infrared sensors (IR). The gas chromatograph readings (GC) show a time lag of about 25 min. The gas Figure 4. The C2+ content changes within 30seconds from 12 to 16% as captured by the advanced gas sensor (green). The engine control follows the signal of the gas sensor (red) with the adjustment of the SEV inlet temperature as a function of C2+ Figure 5. NOx emissions of two GT26 field engines with high

C2+ gas supplies Figure 6. Data from an instrumented GT26 field engine illustrating the relationship between SEV burner inlet temperature and SEV burner metal temperature for all burners. C2+ is constant. The scatter is 100K in metal temperature and 160K in inlet temperatFigure 7. Relative auto-ignition delay times for varying C2/C3 ratios at constant C2+=10.7%. The data are calculated for three kinetic models, GRI3.0 plus two others, A and B. Kinetic model B corresponds best to the experimental data Figure 8. The representation of Thai natural gas with a model gas by matching auto-ignition delay times. The maximum propane content of 43% in the model gas employed in the validation tests in Switzerland represents 30% C2+ content in a Thai natural gas