Pemamek is providing automated multi-layer welding technologies that can significantly increase manufacturing productivity

Automated multi-layer welding solutions as a turnkey for the wind power sector. (Credit: Pemamek)

The energy industry has constantly been growing, and inevitably is at the centre of ongoing global changes; the demands of producing renewable energy are increasing, as are the sizes of monopile foundations. Pemamek is providing automated multi-layer welding technologies that can significantly increase manufacturing productivity.

Transforming manufacturing processes according to market needs is imminent, for reliable, safe and affordable energy. Energy providers require high-quality technology, higher production capacity and cost-efficiency. The diameters, thicknesses and sizes of the wind towers and foundations are rapidly growing. In the future, we might face even such huge dimensions as 15m diameters and 4,000t weights. In the offshore sector, floating foundations in deepwater depths may be a reality soon.

Manufacturing such big constructions and thick materials inevitably bring changes to maintain the process efficient. As a result, welding grooves need to be smaller to reach the required capacity and still maintain high quality. As manual welding is time-consuming, inefficient and there is never a full guarantee of labour safety, automated processes provide the solution. Welding and production automation provides the safety and productivity that manufacturing of such big constructions and thick materials need.

Turnkey solution

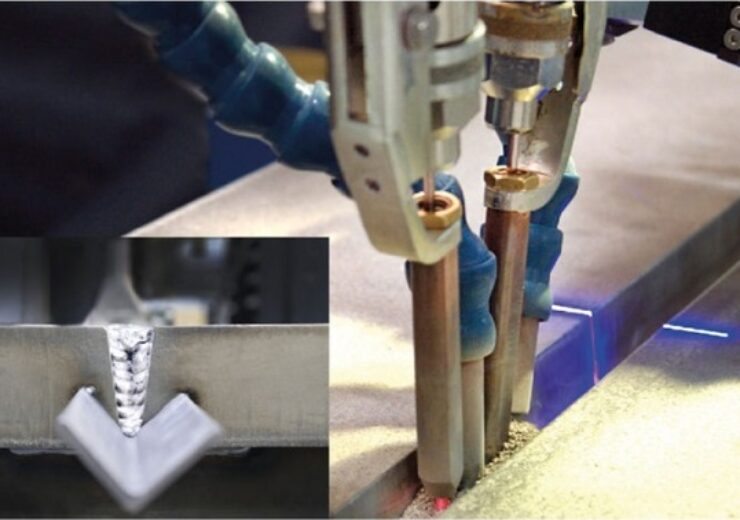

Currently, one of the most efficient and safest ways to weld with the Pema platform is with a tandem long stick-out process combined with Pema WeldControl 500 software, equipped with tiltable welding heads. The control panels are designed to be visual and simple to use and control the whole welding process. This technology and software go hand in hand with heavy material handling solutions such as roller beds and assembly stations. All controls are in one place: welding platform or column and boom functions, seam tracking, full digital integration to Lincoln Power wave, roller beds and positioners.

Broader features enable minimised distortion, better safety and a much faster process. Pema roller beds and positioners integrated into welding column and boom solutions, and combined with special welding automates, have been proved to bring significant improvements in the production process. Highly efficient assembly stations and automated multi-layer welding with laser-based seam tracking have the capability of handling even the biggest foundations on the market. High quality and high performance are crucial in monopile manufacturing, and the welding of thick materials is in the central role of the process. Automated production lines for multi-layer welding processes guarantee efficiency in monopile production with remarkably increased capacity.

The bigger the diameters and wall thicknesses the more challenging it will be to meet operational demands. The Portuguese ASM Industries (ASMI) is specialised in manufacturing towers and foundations for the onshore and offshore wind energy industries. As a part of ASMI’s recent investment, the company acquired PEMA production lines, PEMA columns and booms, roller beds, longitudinal and circular milling machines and a welding platform with two welding heads, among others. By investing in modern PEMA welding automation, ASMI has more digitality and intelligence in its tower manufacturing.

The PEMA welding platform can have one or several welding heads with anti-creep handling solutions, which makes the manufacturing safe and efficient. To ASMI, Pemamek provided a special solution that included a significant amount of new technology, such as laser seam tracking and semi-narrow gap technologies. The transition from traditional submerged-arc welding to semi-narrow gap with laser seam tracking brings total control over wire positioning, ensuring fewer human errors and less-needed skills. The process is increasing welding efficiency significantly, causing less workload as one operator controls multiple weld heads simultaneously. The process brings more flexibility and reliability to the project, decreasing the number of defects.

This article first appeared in World Wind Technology magazine.